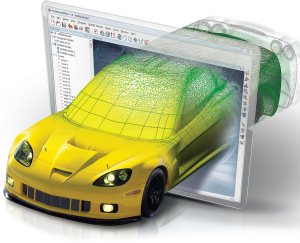

PolyWorks Modeler

Comprehensive Reverse Engineering Software PolyWorks Modeler is a complete reverse-engineering software solutions, enabling users to extract pivotal CAD entities from polygonal models from digitized parts. This serves as the optimal starting point for professional CAD modeling. These optimal CAD entities include:

PolyWorks Modeler is a complete reverse-engineering software solutions, enabling users to extract pivotal CAD entities from polygonal models from digitized parts. This serves as the optimal starting point for professional CAD modeling. These optimal CAD entities include:

- Curves

- Parametric surfaces

- Prismatic features

- Surfaces

Manufacture from Polygonal Models

Manufacture from Polygonal Models

In reverse-engineering, the first step of the workflow is known as meshing, the process of transforming digitized point clouds into a polygonal model. During this process, state-of-the-art data-processing techniques can be applied to the point cloud, such as curvature-based sampling and point smoothing. Because of this, users receive polygonal models that are more compact, more precise and less noisy compared to raw measurements. Polygonal models can be:

- Directly Milled

- 3D Printed

- Used in Aerodynamic Simulation Software

PolyWorks Modeler features two different categories of tools for editing polygonal models:

- A tool set designed to repair and optimize imperfectly digitized geometry. For example, it may be necessary to interpolate new polygons over unmeasured areas to create a complete surface representation.

- A tool set of tools offering CAD operations on polygonal models, such as extrusion, offset, fillet, and Boolean operations.

Create CAD-friendly Freeform Surfaces

While most professional CAD/CAM software don’t typically provide 3D modeling tools for polygonal model, PolyWorks Modeler provides its users with an intuitive surfacing features that first lays the curves down on a polygonal model and then intersects them automatically in order to create four-sided or N-sided trimmed non-uniform rational basis spline (NURBS) patches. From here, the NURBS patches are used to control the fitting of a continuous network of NURBS surfaces. Users are then able to export these fitted surfaces to IGES or STEP files and import them into their CAD/CAM software of choice for further editing and processing. The NURBS surfacing technology within PolyWorks Modeler provides incredible surface quality in an extremely time efficient manner thank to the following features:

- Intuitive curve reshaping methods and curvature-continuous curves

- The best NURBS surface-fitting engine on the reverse-engineering market in terms of quality (accuracy, smoothness, and continuity) and flexibility (trimmed surfaces and T-junctions, curvature-based two-step fitting process, and the possibility of blending fitted surfaces to an existing CAD model for local CAD reconstruction purposes)

- G2-, G1-, or G0-continuity control over NURBS patch boundaries

- Automatic G2 surface fitting in areas where NURBS patches have a rectangular topology

Build Solid CAD Models from Geometric Entities

Users can now optimize the geometric entities of digitized polygonal models for extraction and transfer them to a feature-based solid CAD modeler in order to ensure that associative, parametric and fully-editable sold models are generated.

One of the main components in the work flow of solid modeling is parametric 2D sketches. These contain a variety of planar entities – arcs, circles, line and splines – that are defined on a plane that is embedded in a 3D space. With PolyWorks Modeler, solid base features are produced from these 2D sketches by using the Extruce, Revolve, Sweep and Loft tools. Sketches are generated in these steps:

- Defining a sketch plane

- Computing a sketch outline by slicing cross-sections of the digitized model or extracting its silhouette edge

- Anchoring and fitting sketch entities and dimensions, guided by the sketch outline

From here, the parametric sketches are transferred into the solid CAD modeler using an add-in such as SolidWorks. Users can then:

- Combine sketches and non-uniform rational basis spline (NURBS)

- Use the dimensions from fitted prismatic geometry

- Design their desired solid model

Revolutionary Technological Features

Revolutionary Technological Features

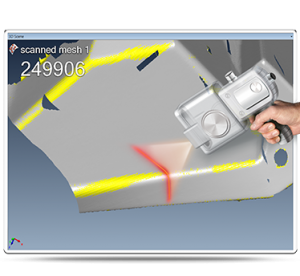

- Universal 3D Metrology Design: The architecture of PolyWorks allows for the integration of manually-operated & numerically-controlled digitizing of the point cloud and 3D measurements from single-point probing technologies within one common infrastructure. This revolutionizes universal inspection and enables the exchange of useful information between devices.

- High Quality, Real-time Meshing: This technology converts 3D scan data from laser scanners into a intuitive metrology process through the real-time creation of polygonal models for products and parts. In addition to this, the real-time quality meshing feature also identifies ineffective scanning methods by identifying quality metrics. This allows users to improve the quality and accuracy of their measurements and provides measurement repeatability.