-

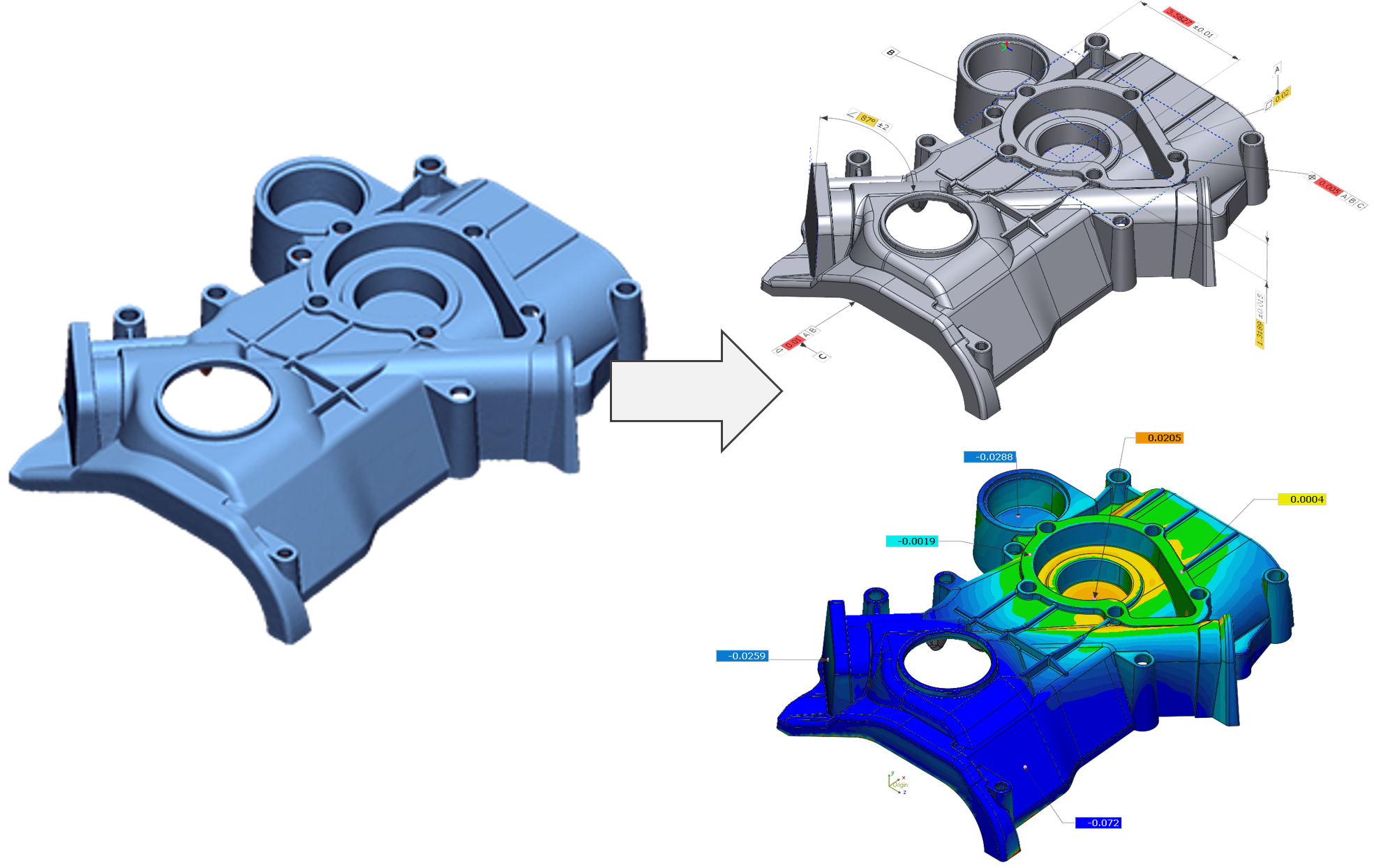

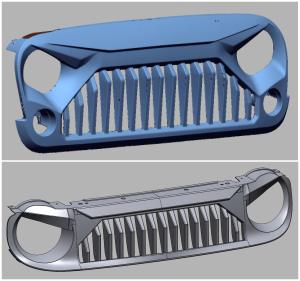

More accurate than manual methods: compare CAD to scan at every step of the reverse engineering process.

-

Free up your engineering resources to work on new projects, while our team develops CAD of existing parts.

-

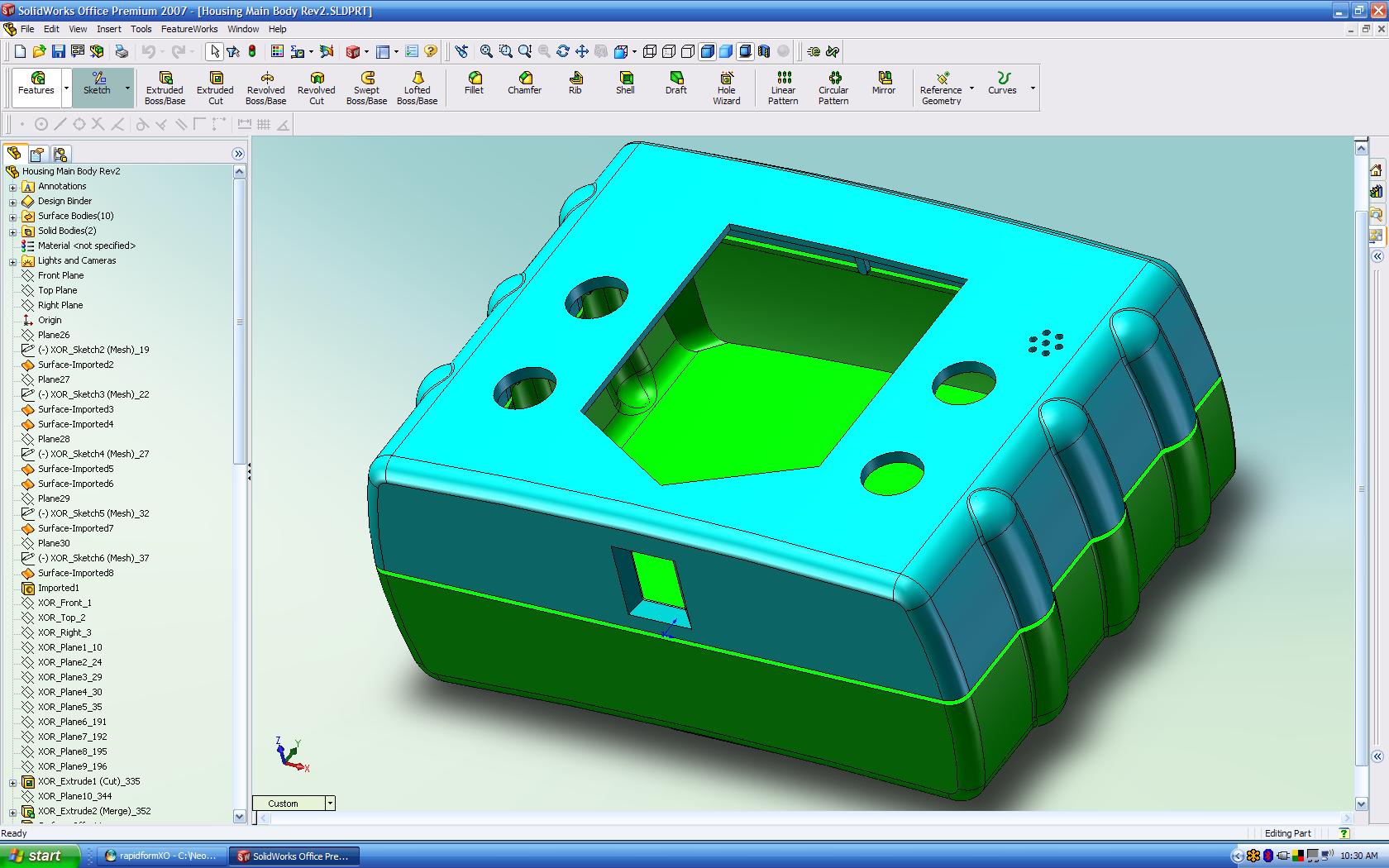

Import final CAD models into common CAD systems such as Solidworks, Autodesk Inventor, PTC Creo, Dassault Catia, and more.

Ultimate Scan-to-CAD Solutions

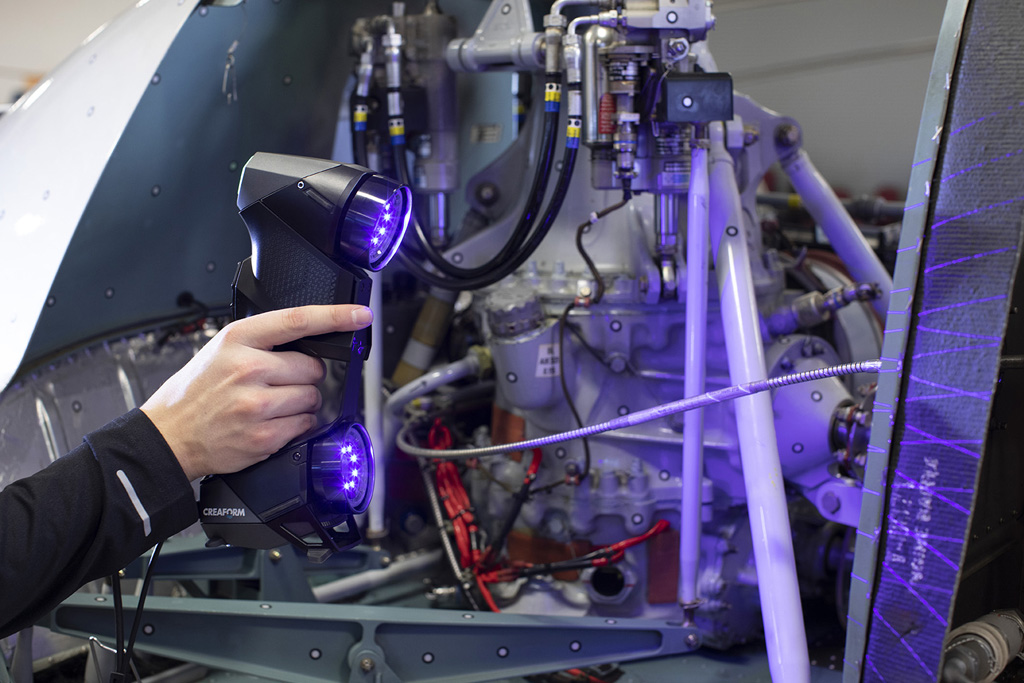

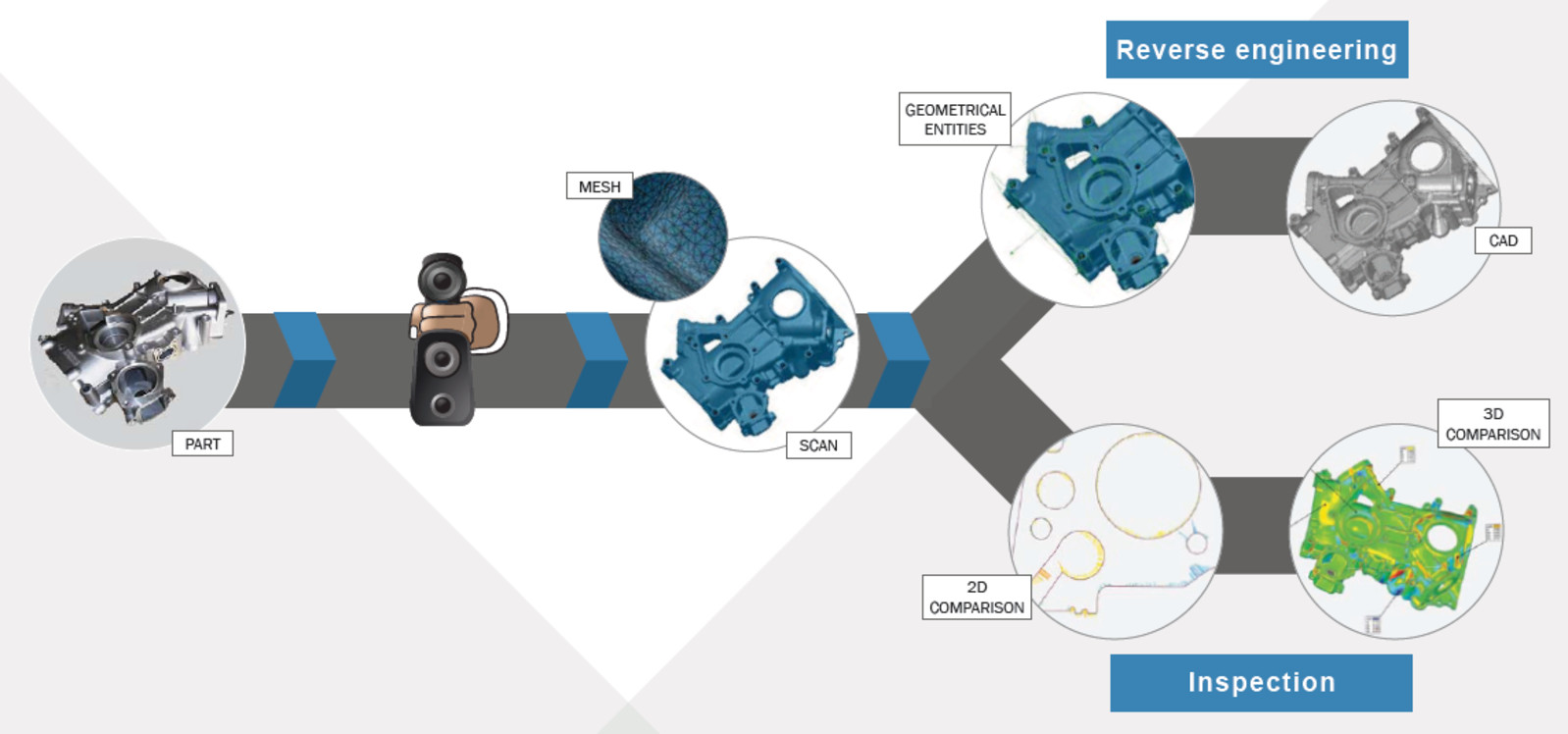

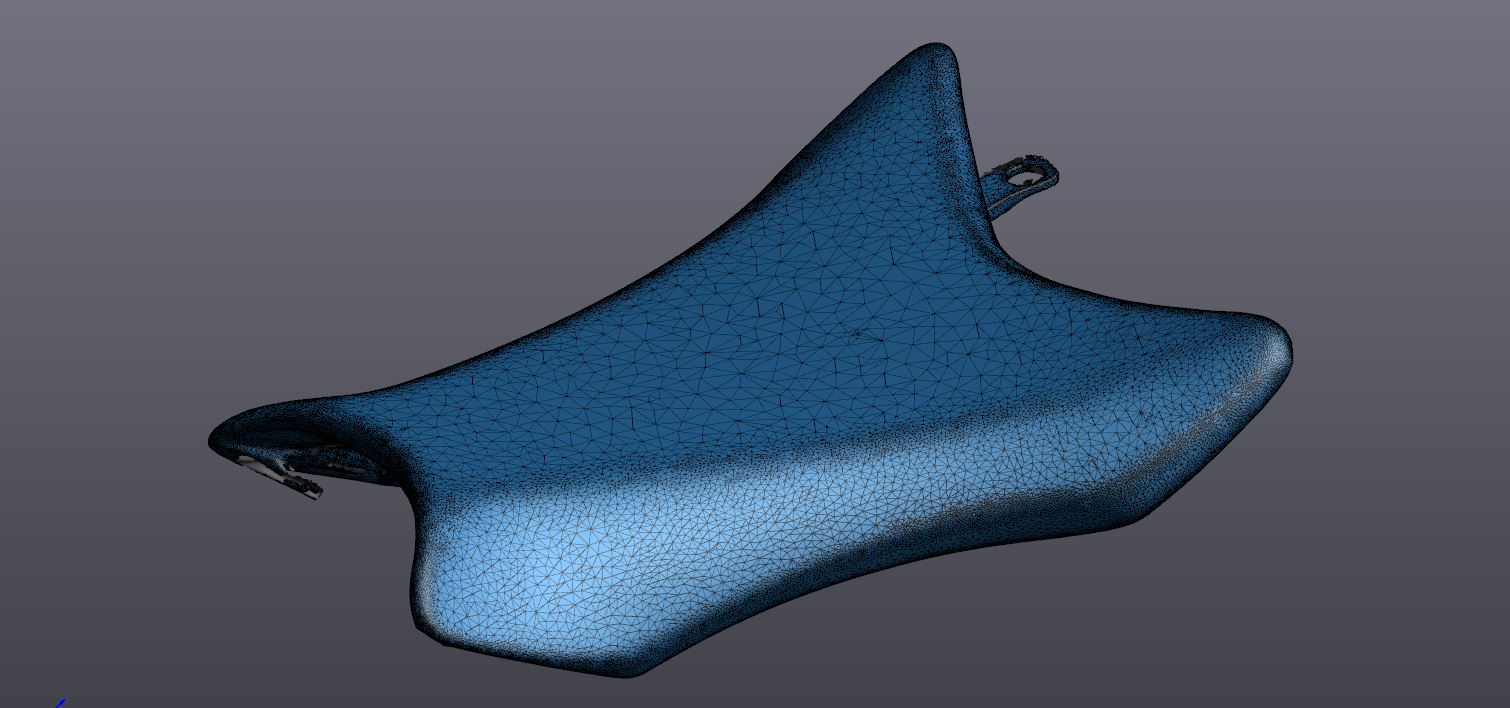

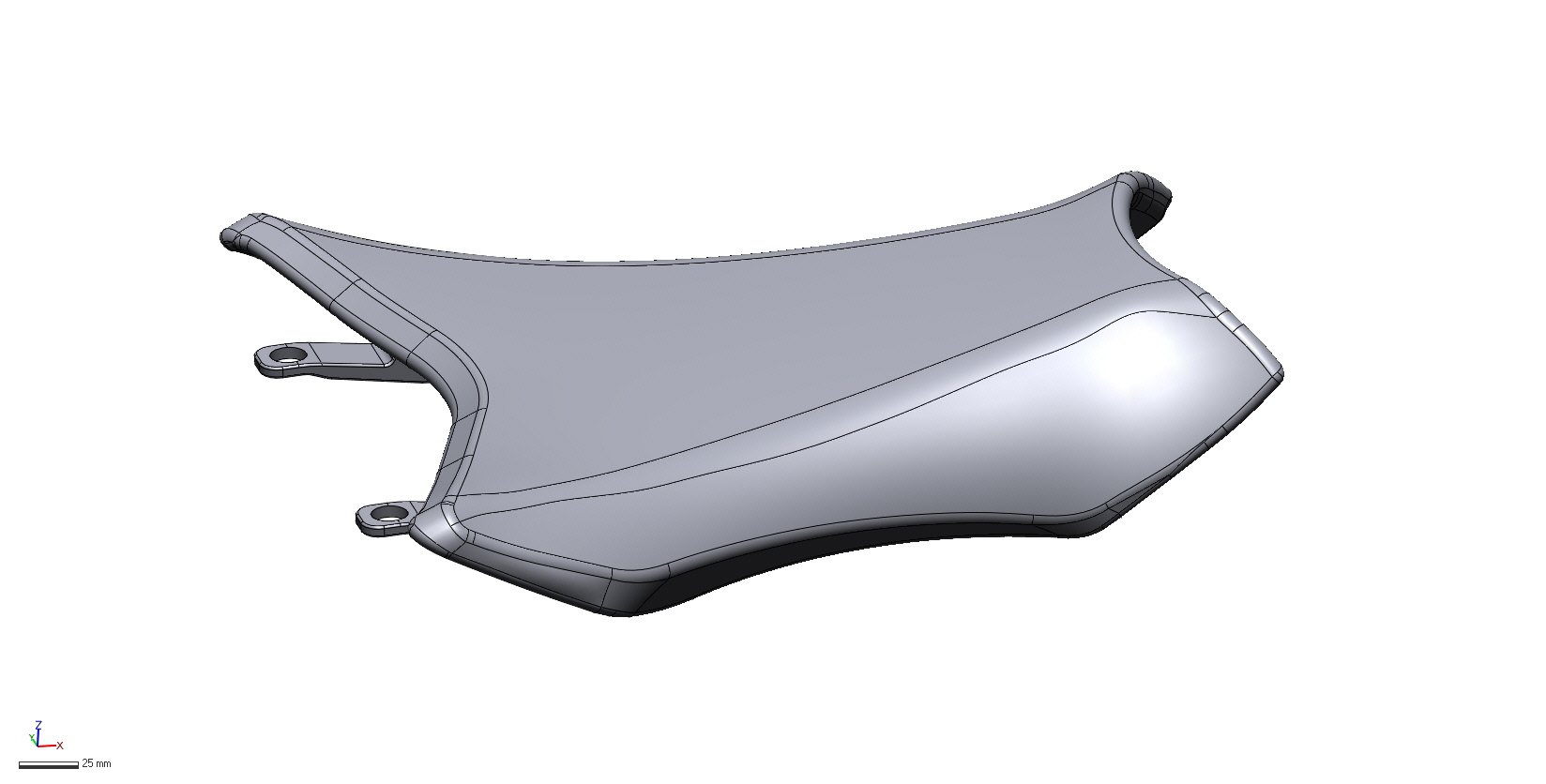

Our process starts by 3D scanning the original part to obtain highly accurate data. Our team uses the latest technology from Creaform, including the HandySCAN, MetraSCAN & Go!SCAN. The raw data is then converted into CAD by our team of highly experienced engineers using software tools like Geomagic Design X, Wrap & Ansys SpaceClaim.

Final CAD models are generally delivered as IGES, or STEP files. However, using our Live-Transfer technology, we can deliver fully parametric models with history for our clients using Solidworks.

We specialize in 3D Scanning for Reverse Engineering and Inspection!

What types of 3D models can I get from NeoMetrix?

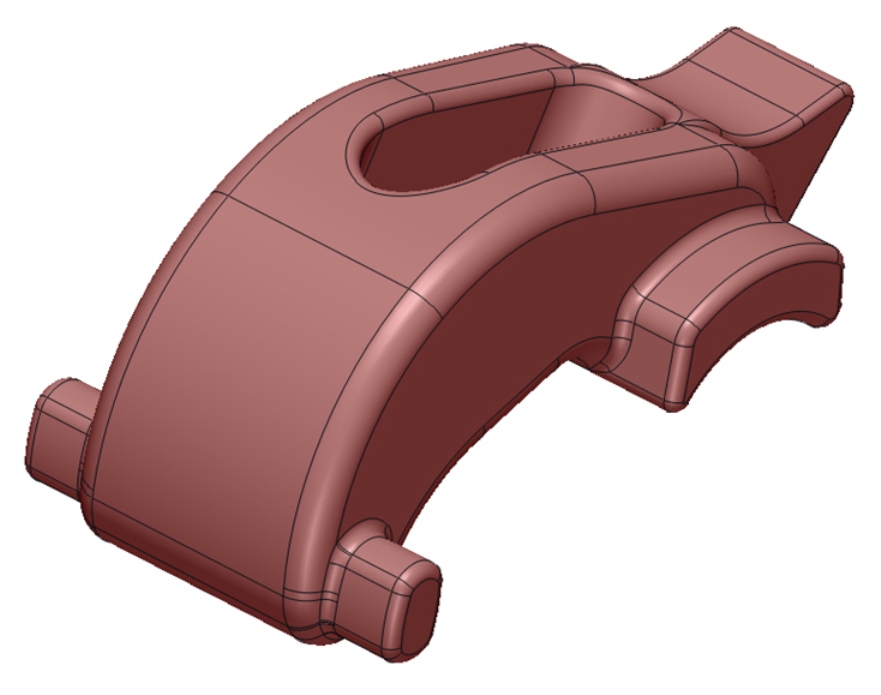

PARAMETRIC SOLID MODEL

File Format: Solidworks (sldprt)

FEATURE BASED SOLID MODEL

File Format: iges, step, parasolid, Solidworks (sldprt)

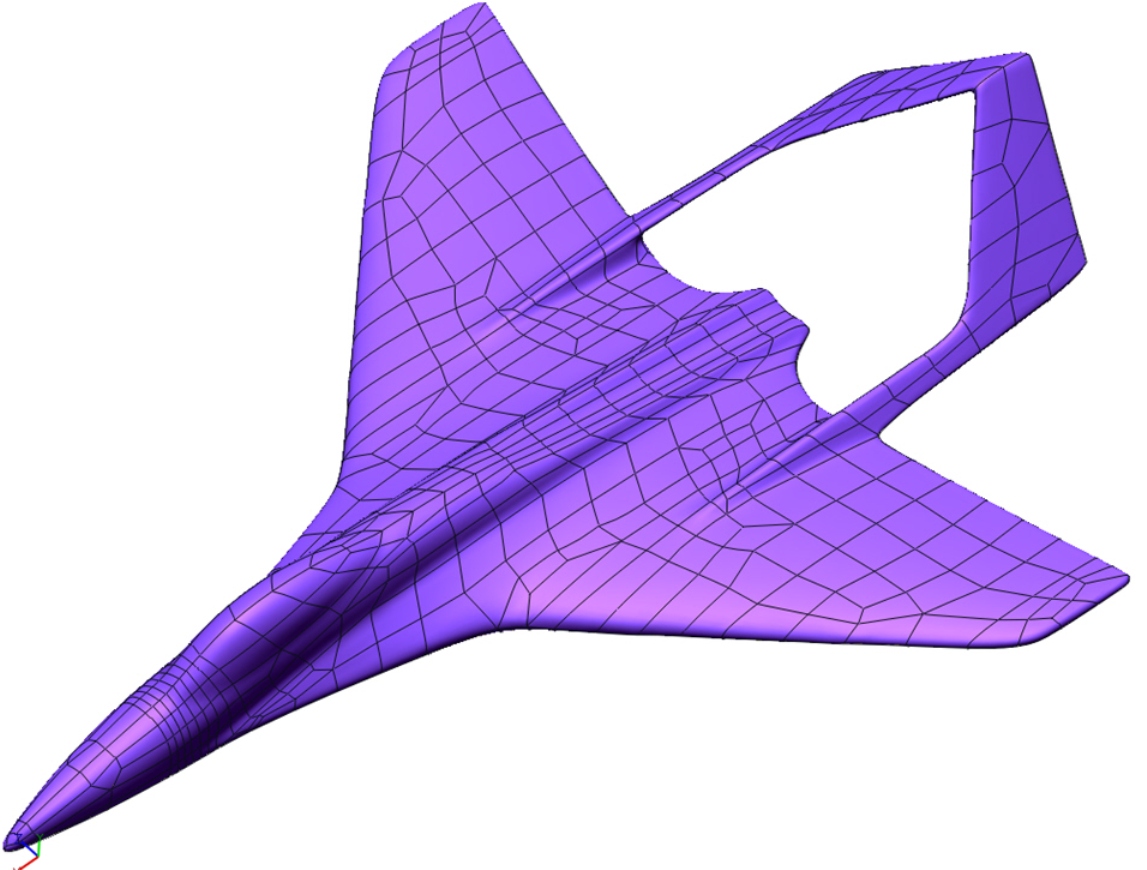

RAPID SURFACE MODEL

File Format: iges, step, parasolid, Solidworks

HYBRID SOLID

File Format: iges, step, parasolid, Solidworks (sldprt)

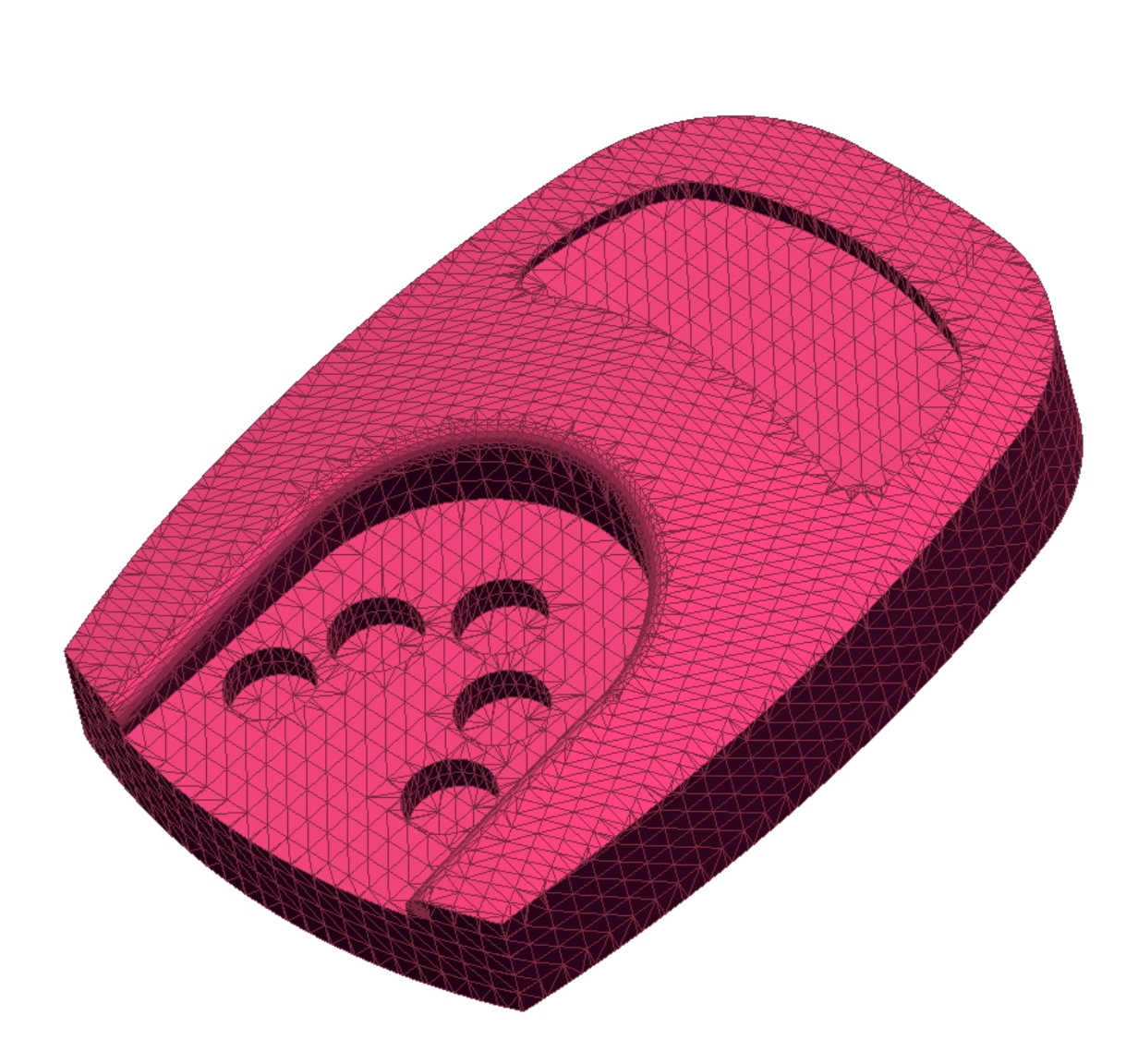

POLYGON MESH

File Format: STL, OBJ, VRML, PLY

ACCELERATE PRODUCT DEVELOPMENT & MANUFACTURING

EXPLORE OUR COMPLETE RANGE OF SOLUTIONS

Your 3D Probems…SOLVED!

Need to get connected? We’re available and ready to find the right solution for you.