Neometrix Services

3D Scanning, 3D Printing , Reverse Engineering, Rapid PrototypingSend your parts to us, or we’ll come to you. No project too big or too small.

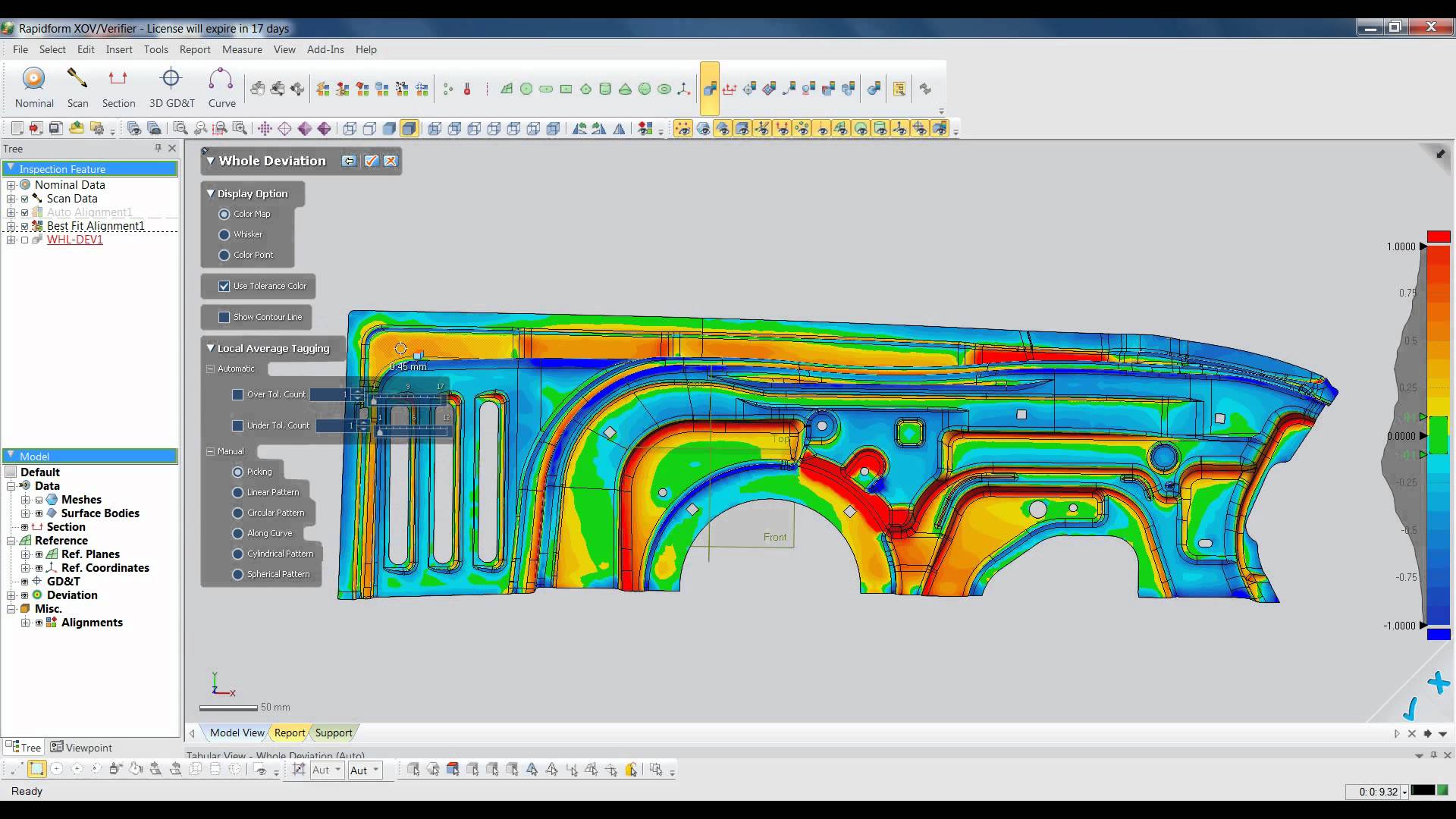

Topographical color maps highlight deviations between the actual part and the design model, clearly indicating out of tolerance conditions with far more clarity than traditional CMM reports.

Sectional views allow for dimensioning just like a 2D print, while also supporting full GD&T.

NeoMetrix utilizes 3D Systems & Markforged 3D printers to create accurate, clean, smooth and highly detailed 3-dimensional models.

Hundreds of material options are available.

Professional Training

We are ready to share our knowledge and experience with your team. With 20 years of experience in the industry, no one is more qualified to provide training on the following systems:

- 3D PRINTERS: Markforged, BigRep, INTAMSYS, & Nexa3D

- Creaform & Steinbichler 3D Scanners

- Geomagic Software- Design X & Control X

- Discovery SpaceClaim Software

NeoMetrix has standard courses available, or we can develop an application-specific program tailored to your needs. Training can be conducted at our facility or yours.