Featuring dynamic referencing and volumetric accuracy optimization, this 3D measurement solution is engineered to work in harsh environments and deliver high accuracy on large measurements, regardless of the user’s experience level.

- Accuracy of 0.075 mm (0.003 in)

- Resolution of 0.1 mm (0.0039 in)

- 2.25 measurements/s

- Part size is 1-15 m (3.3 – 49.2 ft)

- Expert NeoMetrix Support/Training Included

- Software- VXelements™

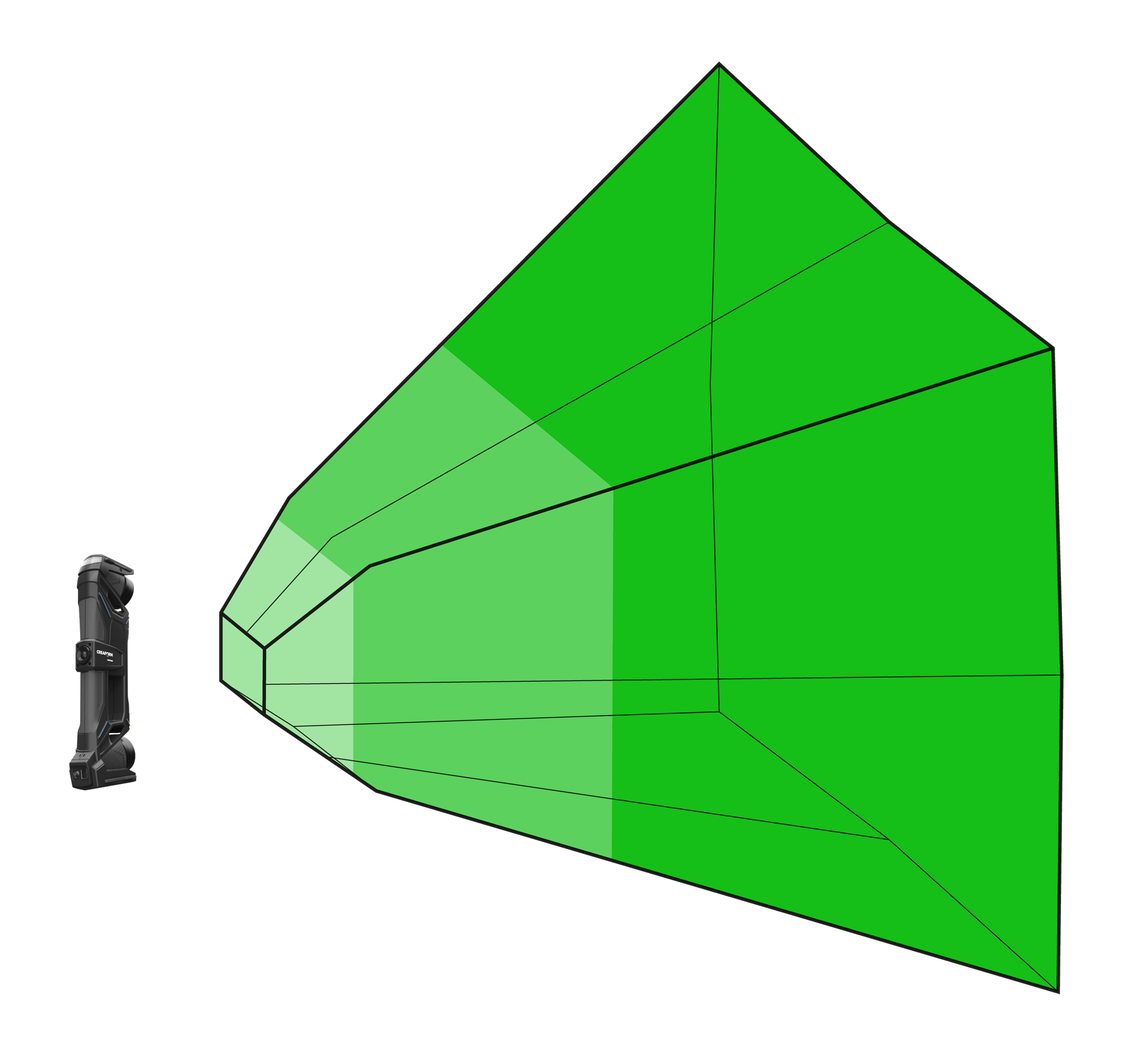

FLEX VOLUME

This enables the user to scan with remarkable quality at a short standoff distance and measure large parts at very high speed from a longer standoff distance.

SMART SURFACE ALGORITHM

Its sophisticated image processing, combined with artificial intelligence, optimizes surface measurements for unparalleled tracking, better performance, better readings of difficult, contrasted finishes, and a simpler scanning process.

REAL-TIME CALIBRATION & VISUALIZAITON

The MAX Series integrates the calibration step directly into the scanning workflow, performing it automatically and seamlessly.

With a volumetric accuracy of 0,100 mm + 0,015 mm/m, ISO 17025 accreditation and compliance with the VDI/VDE 2634 part 3 standard, it provides metrology-grade results, ideal for QC/QA, precision link between parts and demanding reverse engineering of large parts.

ULTIMATE 3D SCANNING SOLUTIONS FOR INNOVATORS

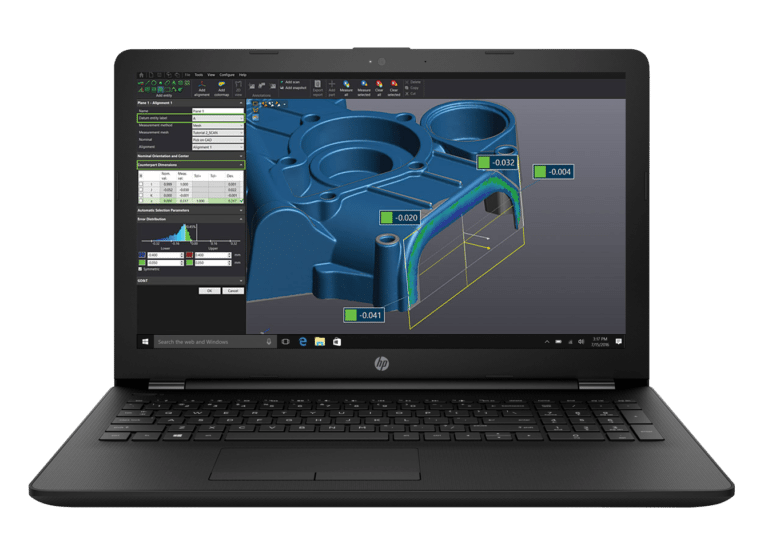

3D SCANNING & REVERSE ENGINEERING

COMPUTER-AIDED INSPECTION & ANALYSIS

With computer aided inspection, part production is faster and the parts are much more accurate by eliminating manufacturing errors in advance.

PROFESSIONAL TRAINING: OPERATING 3D SCANNERS

In addition to basic operation training, we can also provide application specific training designed to meet your organization’s unique needs!

Looking for the ultimate portable metrology-grade 3D Scanner for product development and quality control?

Our experts will find the best solution for you and your application HOW TO BUYAccuracy

Part size range (recommended)

Working Distance

HandySCAN MAX™

0.150 mm , (0.0059 in)

1-10 m , (3.3–32.8 ft)

0.45 to 1.6 m , (1.5–5.2 ft)