Comet L3D

Steinbichler Optotechnik proudly presents COMET L3D – a bright new star in the 3D digitizing universe. Featuring innovative LED lighting technology, the extremely compact high-performance 3D sensor adds a new dimension of efficient 3D data acquisition.

The new ultra-portable sensor makes 3D data acquisition even faster, easier and more accurate. It is the ideal cost-effective entry level solution for users who want to take advantage of the extensive functionality of optical metrology without compromising performance, technology or data quality.

COMET L3D performs excellently even in demanding applications such as quality assurance. Its rugged design, the dustproof enclosure for the optical components of the sensor head, and the high-quality connectors allow use in industrial environments. The sensor is controlled via an industrial standard CAN bus interface. Thanks to its ultra-compact size and light weight, you can position the sensor using standard accessories (e.g. camera stands). Transport, setup and commissioning of the overall system take very little effort. Designed for easy handling and use, COMET L3D offers you maximum flexibility and efficiency in all your measurement tasks.

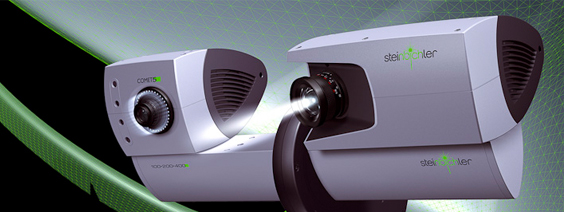

Comet V

3D digitizing in revolutionary shape: With the COMET5 sensor, Steinbichler Optotechnik is presenting a system perfectly fitting the steadily growing application requirements from the industry, in particular for product development and quality control. COMET5 combines unique performance and ease of use making it the ideal solution for demanding applications.

Based on industry-proven foundations, the COMET5 with its new projection technology reaches new performance levels for high-speed measurements. This is enabling the data acquisition in the digitization process to be completed in 1/6 th. of the time which is a deciding advantages when measuring in rough industrial environments prone to vibration. The consequent utilization of the latest PC hardware and software technologies (parallel processing, 64 bit operation system and application software) furthermore enables an extremely fast post-processing of the measured data. The combination of the proven one-camera-technique and the newly developed projection technology guarantees high-speed measurements as well as excellent data quality. COMET5 completes all measurements fast and accurately and is therefore ideally suited for efficient use in quality control next to the production line.

The rigid construction of the system is extremely stabile which allows the system to be operated in a wide temperature range and the high-power external light source further improves the system temperature stability. Owing to its high physical stability, the sensor is perfectly suitable for automated measuring applications. The sensor can be operated on an industrial robot without the risk of acceleration forces influencing the measuring accuracy. COMET5 thereby guarantees a high reproducibility of the highly accurate measurement results, in addition to having the advantage of minimizing the need for system recalibration.

COMET5 is through its robust construction made for mobility and a variety of handling systems are available for the positioning of the system. The modular design allows for quick and easy adaptation of the system to the measurement volume required by the application and thereby offers the maximum of configuration flexibility for each individual measurement task. A custom designed zoom lens in the projection module offers exceptional optical features – thus, the change between different fields of view can conveniently be performed.

Specifications

COMET5 1.4M

| Camera Resolution | 1360 x 1024 |

| Measuring Volume in mm³ 50 100 200 400 800 |

46 x 34 x 50 110 x 82 x 70 220 x 164 x 140 444 x 330 x 250 890 x 660 x 500 |

| 3D Point Distance in µm 50 / 100 / 200 / 400 / 800 |

33 / 80 / 160 / 320 / 650 |

| Shortest Measuring Time in Seconds | 0.6 |

| PC | 1 x Intel Xeon Quadcore, 12 GB upgrade up to 24 GB |

| Sensor Positioning | tripod or sensor stand with manual turn and tilt axis, robot |

| Automatic Object Positioning | rotation table, robot |

COMET5 2M

| Camera Resolution | 1600 x 1200 |

| Measuring Volume in mm³ 50 100 200 400 800 |

– 85 x 65 x 60 180 x 135 x 140 400 x 300 x 250 800 x 600 x 500 |

| 3D Point Distance in µm 50 / 100 / 200 / 400 / 800 |

– / 55 / 115 / 240 / 500 |

| Shortest Measuring Time in Seconds | 0.6 |

| PC | 1 x Intel Xeon Quadcore, 12 GB upgrade up to 24 GB |

| Sensor Positioning | tripod or sensor stand with manual turn and tilt axis, robot |

| Automatic Object Positioning | rotation table, robot |

COMET5 4M

| Camera Resolution | 2048 x 2048 |

| Measuring Volume in mm³ 50 100 200 400 800 |

55 x 55 x 50 80 x 80 x 60 190 x 190 x 140 380 x 380 x 250 760 x 760 x 500 |

| 3D Point Distance in µm 50 / 100 / 200 / 400 / 800 |

25 / 40 / 95 / 190 / 380 |

| Shortest Measuring Time in Seconds | 0.8 |

| PC | HighEnd Workstation: 1 x Intel Xeon Quadcore, 24 GB Upgrade optional: 1 x additional Quadcore CPU, up to 96 GB |

| Sensor Positioning | tripod or sensor stand with motorized turn and tilt axis, robot |

| Automatic Object Positioning | rotation table, robot |

COMET5 11M

| Camera Resolution | 4016 x 2688 |

| Measuring Volume in mm³ 80 150 350 600 1000 |

75 x 50 x 50 155 x 105 x 70 345 x 230 x 200 560 x 375 x 370 900 x 600 x 600 |

| 3D Point Distance in µm 80 / 150 / 350 / 600 / 1000 |

18 / 38 / 85 / 140 / 225 |

| Shortest Measuring Time in Seconds | 4.0 |

| PC | HighEnd Workstation: 1 x Intel Xeon Quadcore, 24 GB Upgrade optional: 1 x additional Quadcore CPU, up to 96 GB |

| Sensor Positioning | tripod or sensor stand with motorized turn and tilt axis, robot |

| Automatic Object Positioning | rotation table, robot |