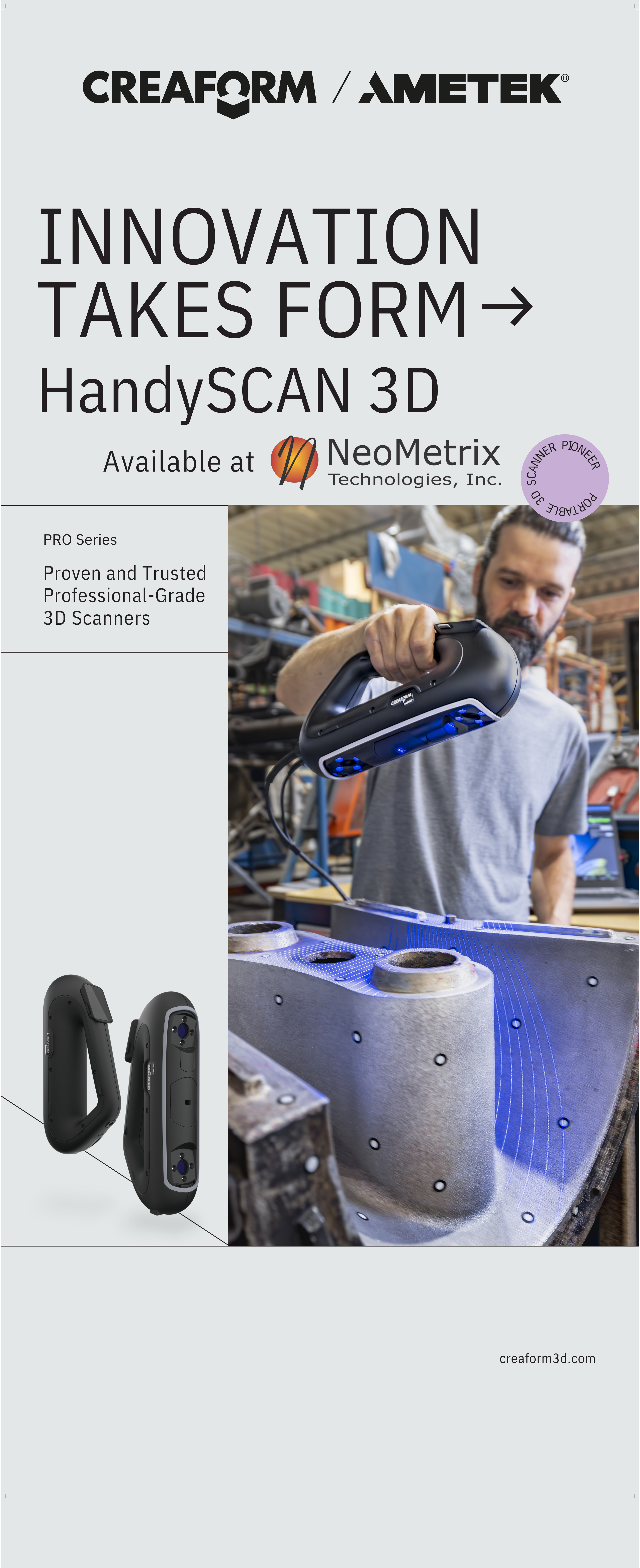

The HandySCAN PRO Series delivers unmatched accuracy, speed and portability — designed for reverse engineering, inspection and product development workflows in industrial environments. No tripod or external tracking system required, so you can scan complex parts on the shop floor or out in the field.

Top Features:

- Accuracy Up to 0.025 mm (0.0009 in)

- Volumetric Accuracy-0.020 mm + 0.060 mm/m (0.0008 in + 0.00072 in/ft)

- 23 blue laser lines

- Wireless capability

- Touchscreen display

- ISO/IEC 17025 – Based on ISO 10360 standard

- Large scanning area for any part size

- Built-in Display- Real-time operator guidance – Photo Camera Integration

- Augmented Reality – Real-time on-part mesh generation

- Expert NeoMetrix Support/Training Included

- Software- Creaform.OS

Engineered for Precision. Optimized for Efficiency.

PORTABLE DESIGN FOR MAXIMUM FLEXIBILITY

Lightweight and ergonomic, the HandySCAN PRO is built to perform wherever your work takes you — from the shop floor to the field.

TRUE METROLOGY-GRADE ACCURACY

Achieve repeatable, high-precision measurements even in challenging environments. The HandySCAN PRO delivers reliable accuracy trusted by engineers and manufacturers worldwide.

HIGH-RESOLUTION DATA CAPTURE

Capture the most intricate surface details and sharp edges with exceptional clarity. Ideal for components that demand fine feature definition and tight tolerances.

ULTIMATE 3D SCANNING SOLUTIONS FOR INNOVATORS

3D SCANNING & REVERSE ENGINEERING

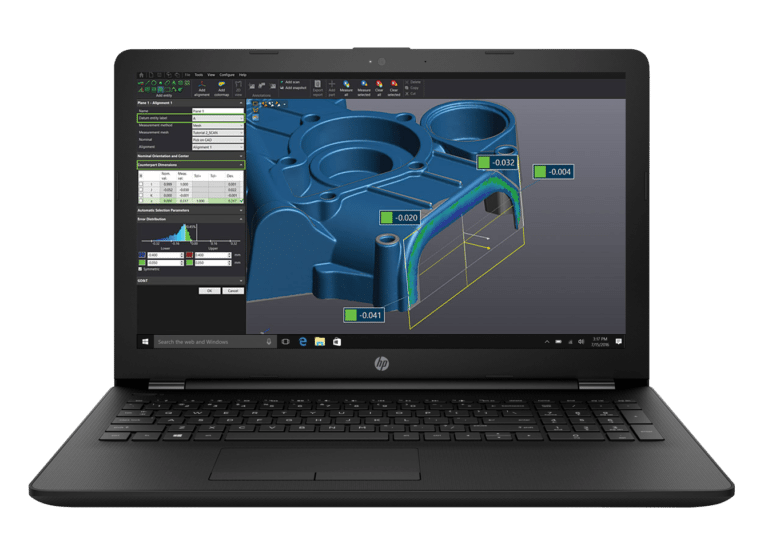

COMPUTER-AIDED INSPECTION & ANALYSIS

With computer aided inspection, part production is faster and the parts are much more accurate by eliminating manufacturing errors in advance.

PROFESSIONAL TRAINING: OPERATING 3D SCANNERS

In addition to basic operation training, we can also provide application specific training designed to meet your organization’s unique needs!