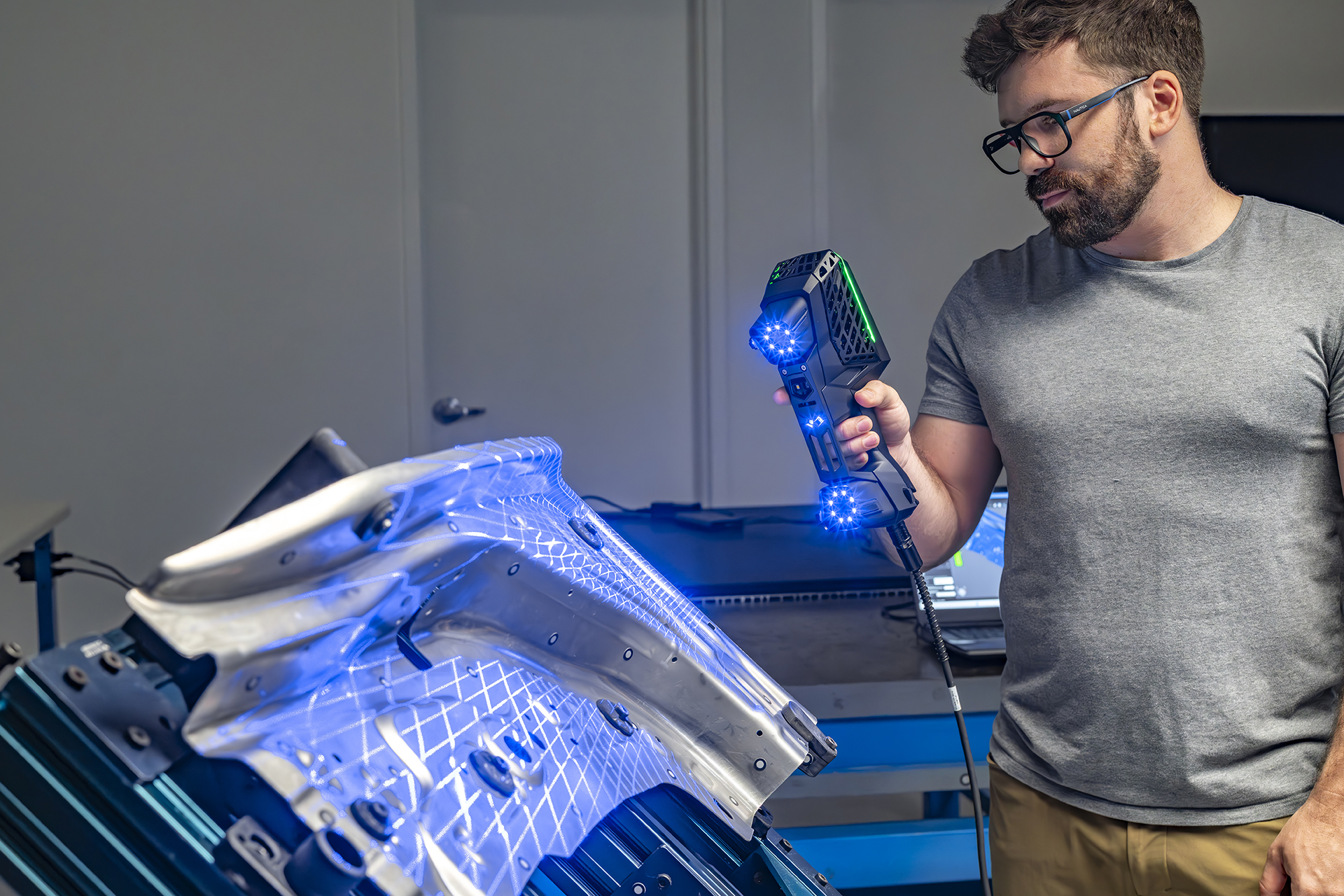

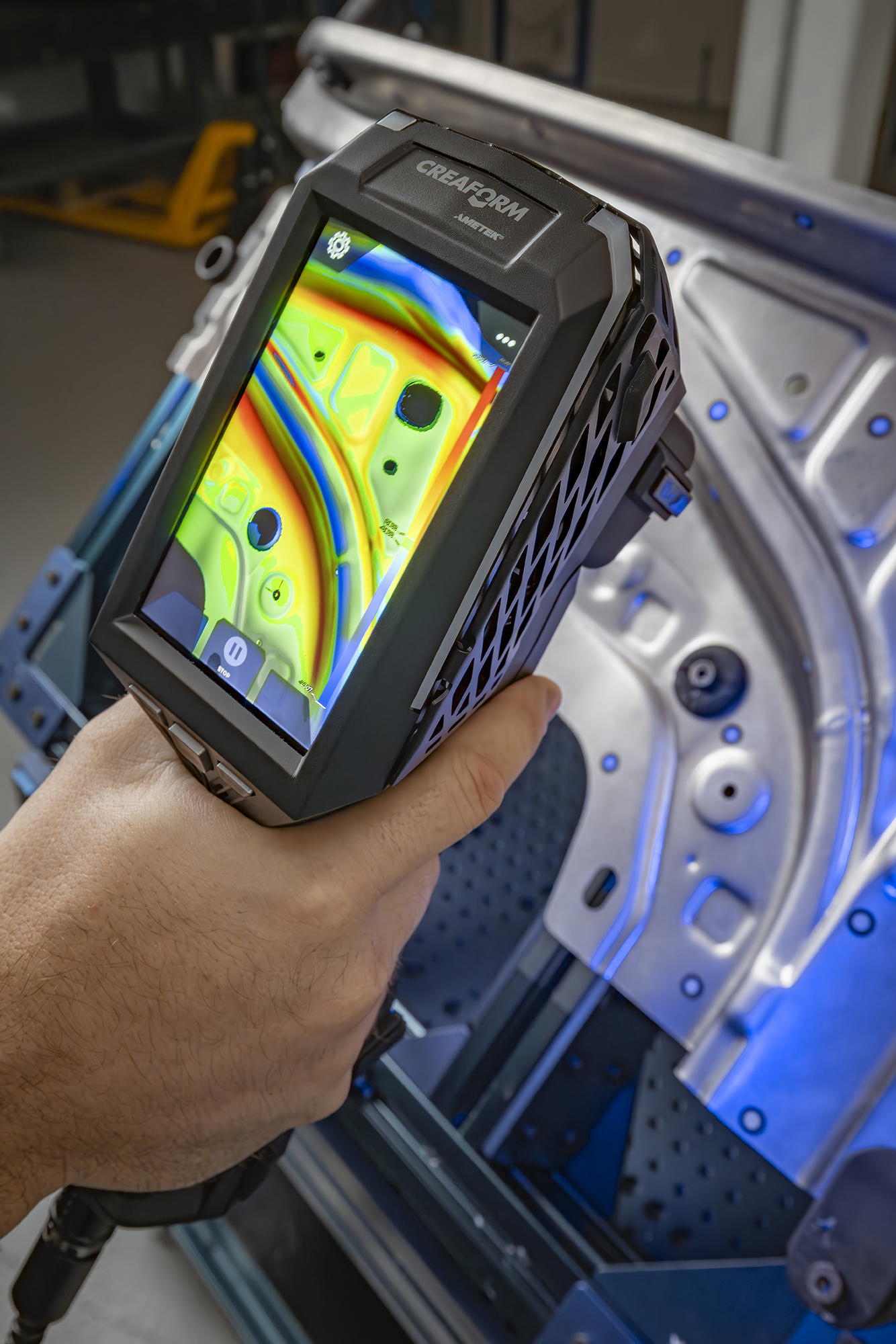

The HandySCAN 3D | EVO Series features a powerful embedded graphical user interface (GUl) that enhances user experience and efficiency while delivering Creaform’s flagship metrology-grade qualities: proven reliability, renowned portability, and unmatched accredited accuracy.

Top Features:

- Accuracy of 0.020mm (0.00079 in)

- Volumetric Accuracy- 0.020mm/m

- 46 Blue laser lines (+1 extra line) & laser pointer

- Wireless capability

- Commitment to metrological rigor ISO/IEC 17025 – Based on ISO 10360 standard

- Large scanning area for any part size

- Built-in Display- Real-time operator guidance – Photo Camera Integration

- Augmented Reality – Real-time on-part mesh generation

- Expert NeoMetrix Support/Training Included

- Software- Creaform.OS

SMART RESOLUTION & AUTOMATIC SHUTTER

Adapts detail capture automatically for every surface. Perfect exposures every time, no manual adjustment needed.

LIVE MESH VISUALIZATION

See your 3D model build in real time as you scan. Instant visual cues keep your scan precise and efficient.

MESH ENHANCEMENT

Delivers cleaner, more detailed meshes with minimal post-processing.

ULTIMATE 3D SCANNING SOLUTIONS FOR INNOVATORS

3D SCANNING & REVERSE ENGINEERING

The ultimate goal of reverse engineering is generally to create a 3D CAD (Computer Aided Design) model for use in the customer’s design system. Using software from Geomagic, PolyWorks, SOLIDWORKS, VXelements, ANSYS and Polyga, we are able to deliver several different types of models which we generate from 3D scanned data.

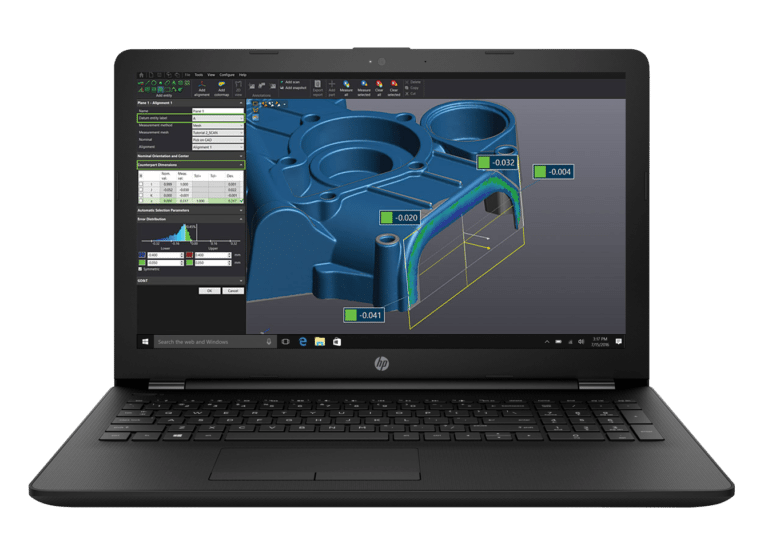

COMPUTER-AIDED INSPECTION & ANALYSIS

Computer Aided Inspection software allows users to process 3D scan data and determine that all part specifications have been met. By providing graphical comparisons between CAD models and parts that can be used for first article inspection, alignment, analysis or wear, validating tooling, and both 2D & 3D geometric dimensioning and tolerancing (GD&T).

With computer aided inspection, part production is faster and the parts are much more accurate by eliminating manufacturing errors in advance.

PROFESSIONAL TRAINING: OPERATING 3D SCANNERS

NeoMetrix offers professional training for all 3D scanning, 3D printing and software products that we represent, including 3D Systems & Markforged 3D Printers, Creaform & Steinbichler 3D Scanners, as well as Geomagic & Discovery SpaceClaim Software. **Included with the original sale of a system, however, we are also to provide add-on training for new employees.

In addition to basic operation training, we can also provide application specific training designed to meet your organization’s unique needs!