3D Scanning to Design Fabric and All-Weather Proof Floor Mats

Development of Automobile Floor Mat DesignsWhile they may not be the most exciting accessory for your vehicle, floor mats are essential.

Whether you live near the beach, have fuzzy pets, or anywhere in between, your car mat protects your carpet, avoids potential corrosion of the underlying foot well metal, and extremely easy to clean.

THE PROBLEM

Developing automobile floormats requires accurate geometric dimensions of the space where they are installed. Aftermarket manufacturers of fabric and all-weather automobile floormats are faced with the challenge of capturing the shape of the floor and the location of nearby objects to precisely design and tailor each floormat set to a specific make and model. Consciously, original equipment manufacturers are very unlikely to share this data; and, to acquire it, oftentimes, third-party manufacturers of automobile accessories pursue traditional ways which can be costly, time consuming, and ineffective.

TRADITIONAL METHOD

A common traditional method used to capture the geometry of the floor and define the location of nearby objects in space includes one dimensional measurements. Engineers must take hand measurements of the space where mats are to be installed. This method is inaccurate and does not depict all the features of the floor.

This lack of accuracy costs time as it lengthens the design process. Engineers get stuck in an iterative loop trying to get a close enough fit, and that is not all. What is more important than that is safety. Following the recent recalls of the Toyota car mats that posed a safety hazard causing accidents across the world, precision and accuracy in floormat development has become a vital element due to stringent regulations and a crucial factor in keeping customers on the road safe.

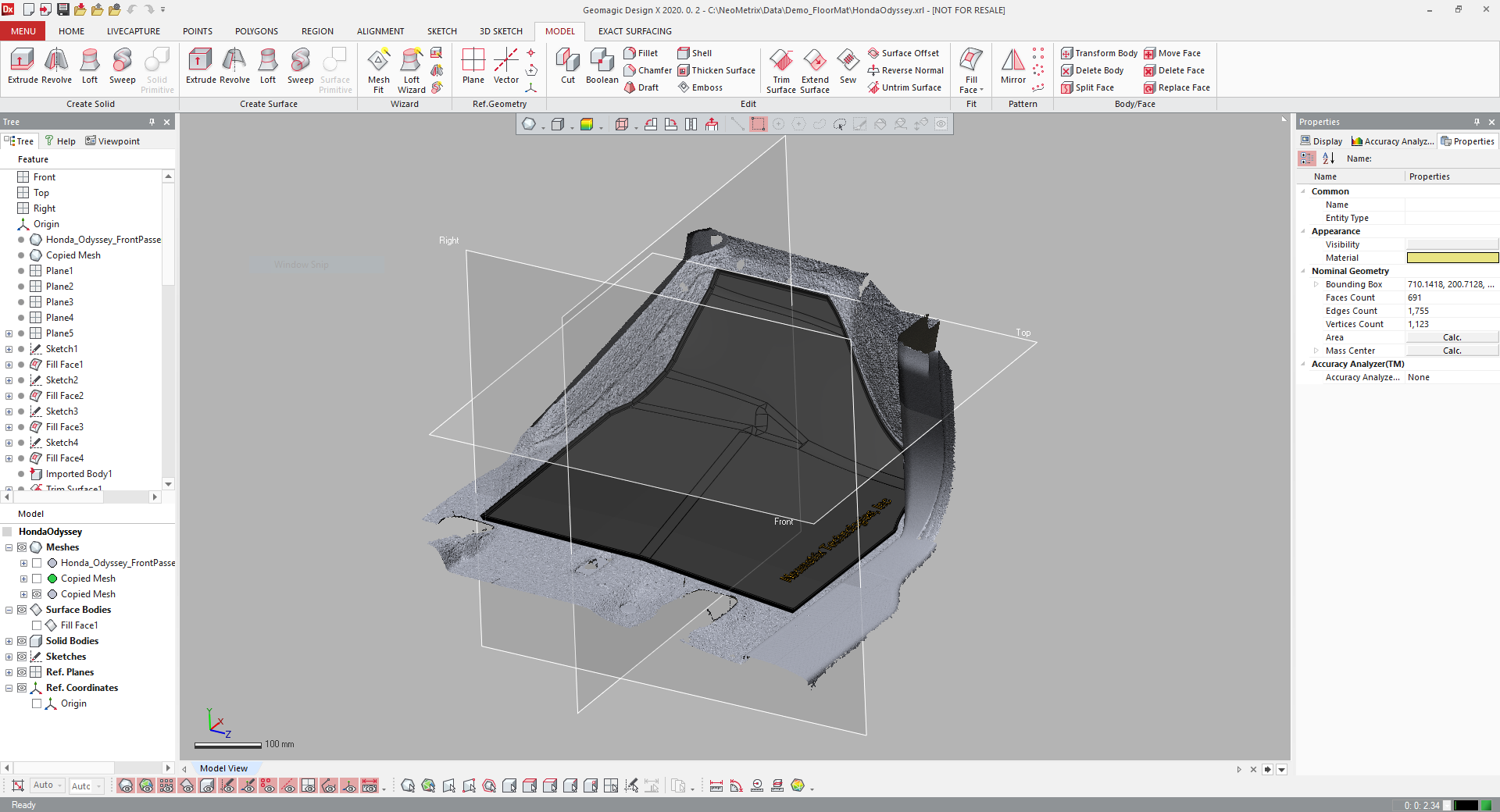

Using the battery powered handheld Creaform Go!Scan Spark, the entire area of the floor where the mats will be installed is digitized in high detail with an accuracy of 0.050mm (0.002in) and a speed of 1,500,000 measurements/s. A three-dimensional mesh made up of a point cloud of the entire geometry of the floor is generated. It is then exported to Geomagic Design X to design and develop a 3D CAD model directly on the mesh just like a tailor would fit a body.

NEOMETRIX ADVANTAGE

There are many advantages to using the NeoMetrix solution. The scanning process only takes minutes to complete. One hundred percent of the geometry of the floor with all its feature and surrounding seat legs, consoles, and pedals can be accurately captured. This way, manufacturers can precisely tailor floormats to each vehicle for a safe and perfect fit.

This method is efficient and cost effective as the mesh scanned data provides the geometry to engineers, on-screen, for an accurate initial design, reducing the number of design iterations and, consequently, the cost of prototyping.

While they may not be the most exciting accessory for your vehicle, floor mats are essential.

Whether you live near the beach, have fuzzy pets, or anywhere in between, your car mat protects your carpet, avoids potential corrosion of the underlying foot well metal, and extremely easy to clean.