3D Scanning, Reverse Engineering & 3D Printing American Flag Pins

The Problem:

One of our clients created a series of flag pins using modeling clay. As an entrepreneurial creation, the client needed to obtain a highly accurate model of these pins, but also wanted to find a cost-efficient solution. The file that he needed had to be prepared for casting methods that are traditionally used to create pieces of jewelry. Wishing to maximize profits, our client also wanted a file he could re-use, should he come across a cheaper methods of productions for the pins – this way he could test the different production options.

Traditional Method:

Software such as Z Brush allows sculptors to create without the risk of erosion or damage that would occur if the sculpture was originally made physically. However, the only way to create a physical sculpture from a digital model – aside from additive manufacturing – is either CNC machining or duplicating it by hand from an artist’s eye. CNC can only carve from one side and wastes materials. In addition, having to physically replicate an original work by hand can deviate from the original artist’s vision; and it can be time consuming taking several revisions.

NeoMetrix Solution:

3D scanning services were provided using the COMET L3D. This 3D scanner is equipped with a compact high-performance 3D sensor which uses innovative structured blue LED lighting 3D scanning technology. The COMET L3D performs excellently even in demanding applications such as quality assurance. Its rugged design, the dust-proof enclosure for the optical components of the sensor head, and the high-quality connectors allow use in industrial environments.

The speed and accuracy of the sensor’s 3D data acquisitions made the COMET L3D the ideal solution, as we wanted to take advantage of the extensive functionality of optical metrology without compromising performance, technology or data quality. 3D scans were taken in-house within a matter of minutes.

Once the 3D scan data was acquired, the mesh was cleaned and edited using Geomagic Wrap. Included with Geomagic Wrap are the “Exact Surfacing” tools with deliver state-of-the-art modeling functions that allow for flawless results. It also allows us to transform point cloud data, probe data and imported 3D formats (STL, OBJ, etc.) into 3D polygon meshes for use in manufacturing, analysis, design, entertainment, archaeology and analysis. With Geomagic Wrap, our 3D workflows for the flags were greatly simplified thanks to the simple functionality.

This software allowed our 3D data to be perfected and used directly for 3D printing on our Stratasys Objet Connex 350 3D Printer. This 3D printer allows us to additively manufacture multi-material parts up to 490 × 390 × 200 mm (19.3 x 15.35 x 7.9 in.) or produce a multitude of different parts simultaneously. The flag pins were printed, cleaned and shipped to our client in just a matter of hours.

NeoMetrix Advantage:

The COMET L3D professional 3D scanner is recommended for quality control/inspection, mold and tool making, rapid prototyping/3D printing, reverse engineering, so it was just perfect tool for the job. It is the ideal cost-effective entry level solution for users who want to take advantage of the extensive functionality of optical metrology without compromising performance, technology or data quality. With Geomagic Wrap, our 3D workflows for the flags were greatly simplified thanks to the simple functionality and intuitive design controls. Using the Connex 350 3D Printer to produce the finish product allowed for us to deliver extremely accurate and fine-detailed finished products to George.

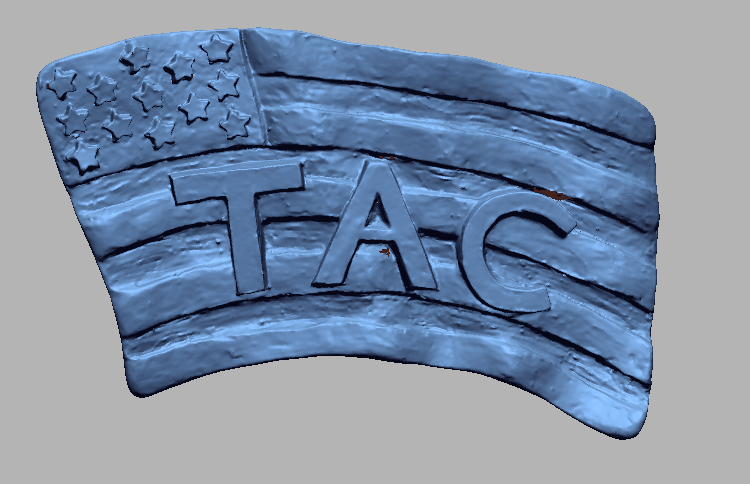

Tag Pin 3D Scan Data

Tag 3D Printed prototype

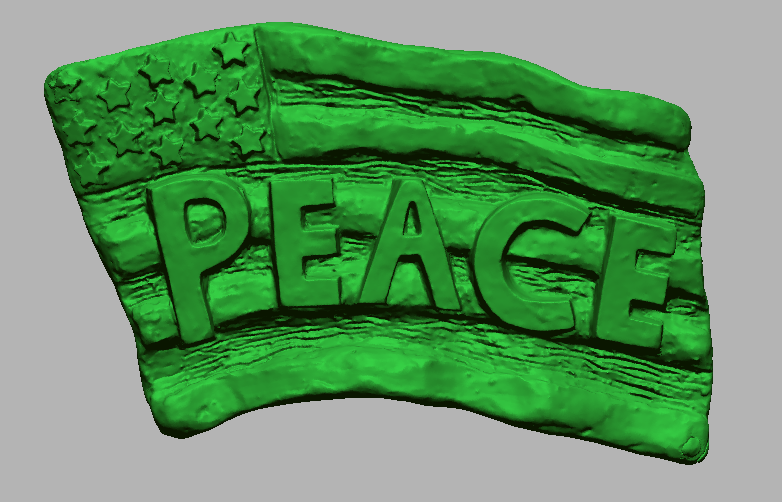

Peace Pin 3D Scan Data

Peace Pin 3D Printed Prototype