3D Scanning & Reverse Engineering a 1972 Datsun 240Z Steering Arm

The Problem:

Restoring, collecting, and racing classic cars is an extremely popular hobby. Unfortunately as the cars age, critical components wear and break down, therefore needing replacement. Such was the case with a 1972 Datsun 240Z steering arm. The goal was to take the worn part, and extract the critical geometry to use for the manufacture of a new one.

Traditional Method:

Obtaining a new component such as a steering arm poses a big problem for classic car enthusiasts: they are often no longer commercially available, and the used market is drying up. Buying an original also means you are replacing your old, worn out part with one of similar age!

Having a complete spare parts inventory for any “just-in-case” scenario generally requires the driver to employ the “2 is 1” concept and keep a second “parts” car on hand.

Those lucky enough to have access to a machine shop have life a little simpler, however the machinist must know what it is they are manufacturing. Traditionally, critical interfacing geometry on these components have to be measured either by hand (leaving much room for human error, and consequently much trial-and-error and hand-fitting), or more recently through the use of a CMM.

NeoMetrix Solution:

By employing the Creaform HandySCAN 700 and a Reverse Engineering software such as Geomagic Design X, a component of known fitment may be pulled from the car, scanned and, recreated in 3D geometry for a machinist.

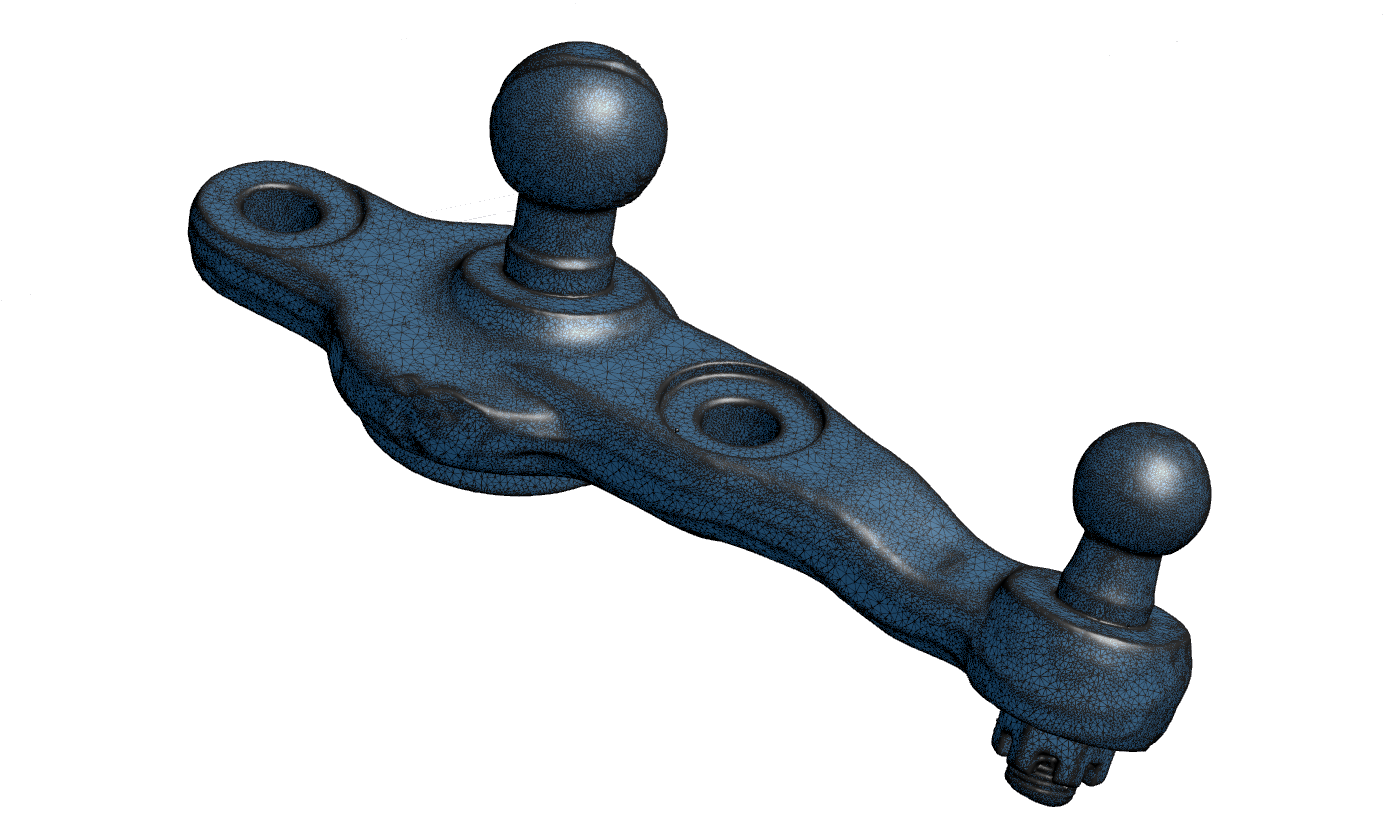

Within minutes, the complete part geometry of the steering arm was captured, and a triangulated mesh generated to within a thousandth of an inch.

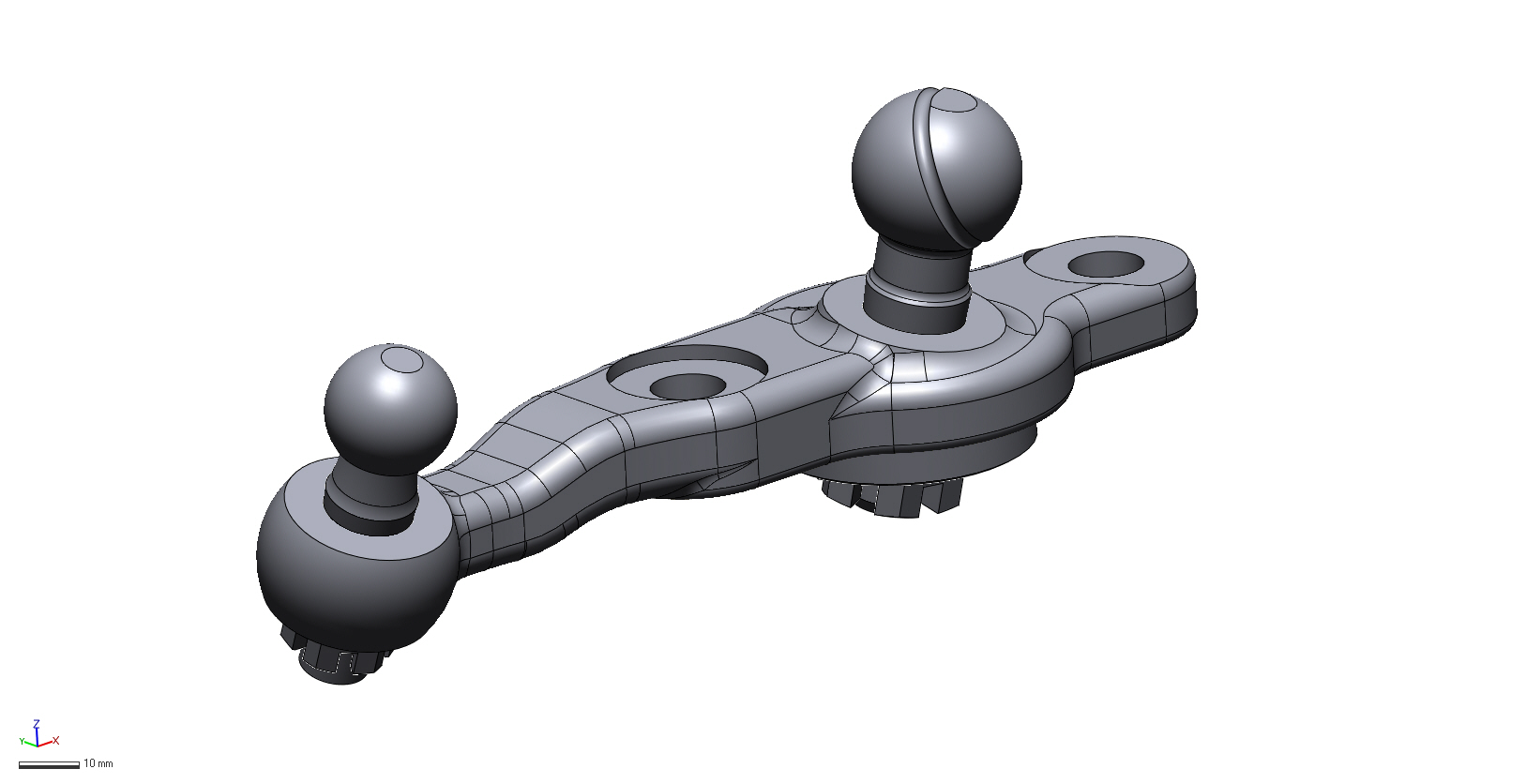

This mesh was then imported into Geomagic Design X, and quickly converted to a CAD file using the software’s advanced feature extraction tools.

NeoMetrix Advantage:

3D scanners yield much greater accuracy than measuring complex components by hand. What would normally be a tedious process to correctly define the exact center-to-center measurement for the spheres, as well as their angle and relation to the main part body, took minutes while utilizing the HandySCAN 700. This method eliminates error stacking between measurements, and ensures that 100% of the required information is captured the first time.

Datsun 240Z Steering Arm to be Scanned

Scanned Data of 240Z Steering Arm

Final Model of 240Z Steering Arm