3D Scanning & Modeling Tooling

3D Scanning & Reverse Engineering services for Metal IndustriesThe Problem:

Metal Industries has almost 100 tooling pieces that are used very often. This tooling degrades over time, as it is made largely of wood. Most of the tooling was originally designed before CAD systems were common or even existed. In order to make replacement tooling, the originals need to be measured.

Traditional Method:

Traditionally, hand measurements or a coordinate measuring machine (CMM) would be used to collect enough points to get a reasonable representation of the tool. These systems are slow, and the amount of data you collect is minimal. This can result in an inaccurate model, causing parts made with the new tooling to not fit correctly.

This process is also time-consuming. When there are almost 100 pieces to model, it is not efficient to hand measure each one.

NeoMetrix Solution:

NeoMetrix uses the latest in 3D scanning technology to be able to capture complex geometry quickly, efficiently and accurately.

The scanner chosen for this project is the Creaform MetraSCAN. The MetraSCAN is a powerful laser scanning system that uses a tracking bar (C-Track) to track the location of the scanner. This means that the object being scanned needs minimal or no reference targets. The laser scanner itself records hundreds of thousands of data points per second, allowing for very quick data acquisition.

Each tool is positioned in front of the C-Track, and is then scanned. With the fast data capture rate, each tool can be scanning in a matter of minutes.

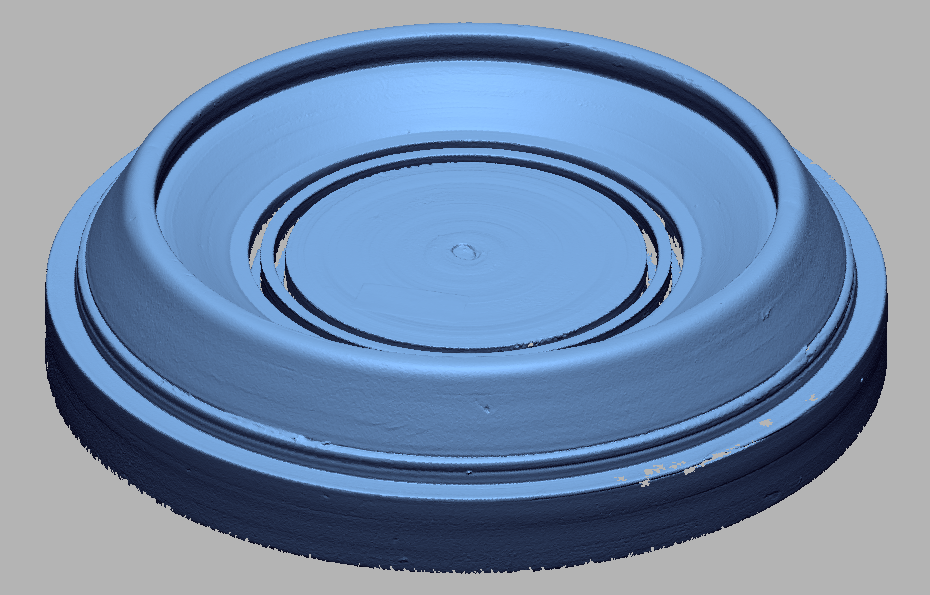

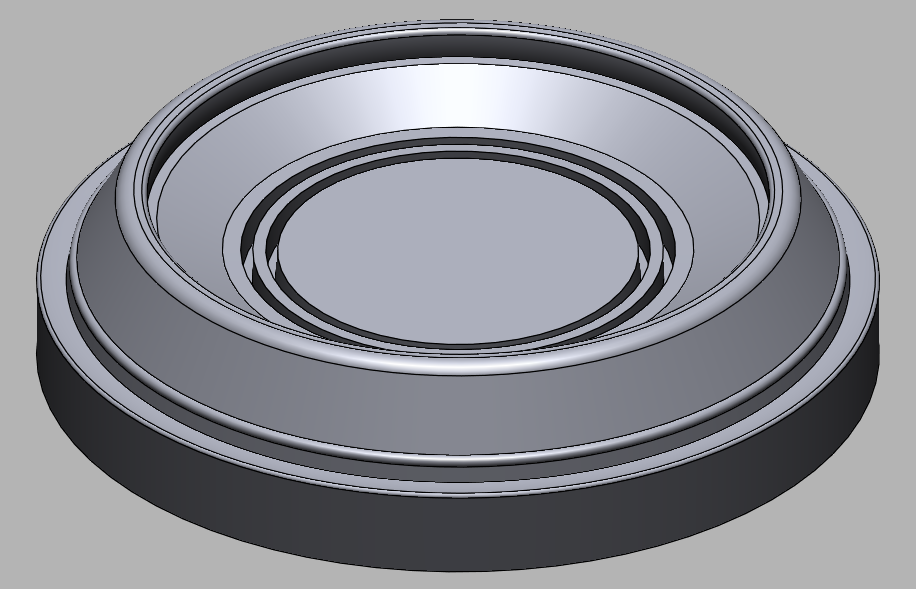

Once the tools are all scanned, the scan data is directly imported into Geomagic DesignX, a powerful reverse engineering software package. Once the data is imported, a model can be created. Using simple sketch tools, a profile of the tool can be extracted from the scan. This sketch can then be revolved to create the entire tool.

This solid file is then exported as a parasolid (or any other standard CAD file type) and then delivered to Metal Industries. They can then use this file to manufacture new tooling.

NeoMetrix Advantage:

The advantages to using 3D scanning and reverse engineering tools are clear. All important metrics of reproducing a part give favor to 3D scanning. 3D scanning saves time and increases efficiency. Where a CMM machine takes a single point measurement per “button click”, a scanner gathers hundreds of thousands of point measurements per second.

The amount of data captured also carries over to accuracy, as any errors get drowned out by the sheer volume of data acquired. With a CMM, if you measure a bad point, unless you measure that same location multiple times, the error will propagate through to the final reverse engineered product.

Being able to easily convert this scanned data into usable CAD data is another key advantage. A solid model that can be imported into any major CAD software package is the most useful type of deliverable. From this solid, the customer can do whatever they want with it, whether it is generating 2D drawings, modifying the design, or using it as a reference for new designs.

Tooling Scan Data

Tooling CAD Model

“NeoMetrix Technologies has saved Metal Industries many, many hours over what they were doing before 3D scanning was utilized. What takes NeoMetrix 30 minutes to do utilizing 3D scanning would have taken them 2 weeks to do with their old process. The time savings alone has been worth thousands of dollars.”

– John Sims, Mechanical Drafter at Metal Industries

About Metal Industries:

Metal Industries has been a leader in the HVAC industry for 70 years. Starting out in an aircraft hangar and growing into a fully fledged manufacturer, they have always focused on providing their customers quality products and services.