Problem:

Heavy metal Dies can be very expensive to replace when they are damaged or worn. Also it is a large problem if there is no cad file or master.

Traditional Method:

If there is no master available the existing female mold must be repaired to create a pattern. Once the pattern is created then the new mold can begin construction.

NeoMetrix Solution:

- Scanned in house using the Konica-Minolta Vivid 9i scanner. (accuracy of .002”)

- Scan Data is registered, merged, and aligned in Rapidform XOR.

- Curvese and sketches are developed based upon the scan data in order to generate a parametric solid (Figure 3).

NeoMetrix Advantage:

- Feasible to obtain quality data previously unavailable by other means.

- Accurate model in Parasolid or IGES formats.

- 3D model available for CNC machining, Rapid Prototype, or run analysis (FEA, CFD).

Get Started Today!

Figure 1 – Original Part

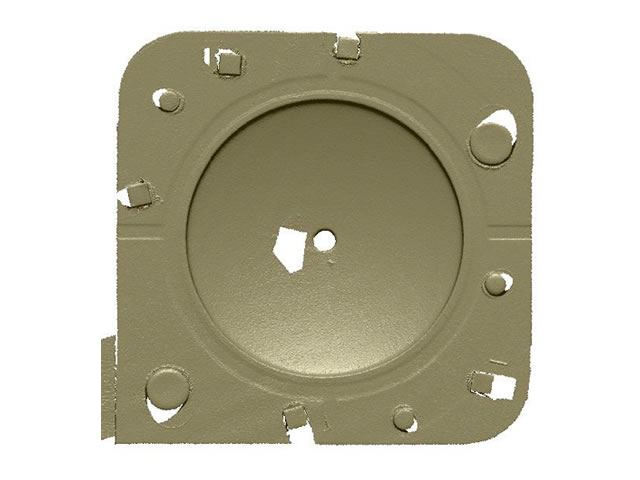

Figure 2 – Raw Scanned Data

Figure 3 – Final Solid Model