Problem:

A customer wanted to recreate an exact replica Cunningham C4R using a buck to shape the metal. Unfortunately the only remaining cars are in private collections or museums. The car was originally designed by hand, and there is no data to define the current shape.

Traditional Method:

The original car would be brought into the shop for 2D patterns and cardboard templates to be drawn. Then they would use these to create a buck, one cross-section at a time. Sheet metal would then be formed over the buck to create the outer panels of the car.

NeoMetrix Solution:

- Travel to Collier Museum in Collier County, Florida

- Car scanned from multiple positions with the Surphaser® 25HSX.

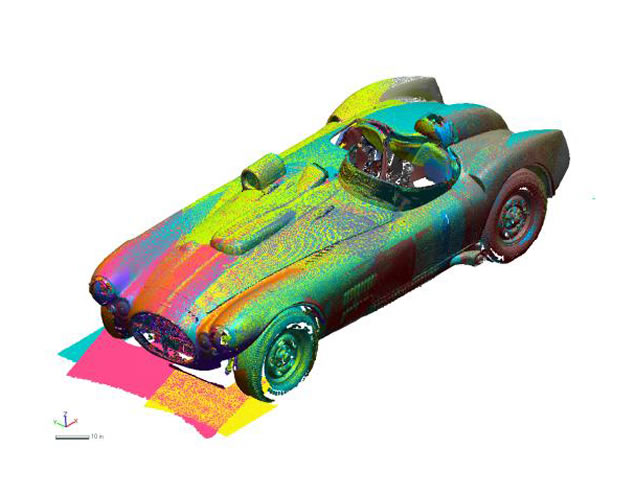

- Multiple scans are aligned in Geomagic Design X

- Scan are merged into a single polygon mesh.

- Rapid surfacing techniques are used to generate a 3D solid model

- Solid model is cut into sections for buck manufacuturing

- Sections are exported as IGES files and used to CNC cut each buck component

- Final buck is assembled for sheet metal fabrication

NeoMetrix Advantage:

- 3D scanning is significantly faster than hand measurements

- 2D sections from solid model are more accurate than cardboard templates

- Digital data set is available for future projects

- Final replica more true to original vehicle

Get Started Today

Figure 1 – Original Race Car

Figure 2 – Scan Data Aligned

Figure 3 – Final Solid Model