3D Scanning an Epoxy Mold

The Problem:

TST Industries is an online business that manufactures aftermarket parts for motorcycles, specifically sport bikes. They approached Neometrix Technologies requesting a digital copy of an epoxy mold. It needed to be highly accurate in detail and be done quickly.

Traditional Method:

Items that have complex shapes or exhibit complex contours can take many man hours to duplicate. Traditional methods call for numerous hand measurements and guesswork that can affect the quality of the part being duplicated. In addition, the task can become increasingly difficult the smaller the part and finer the detail. Physically replicating the part may also require time and numerous iterations before it is eventually approved.

NeoMetrix Solution:.

3D laser scanning offers high quality and rapid solutions for parts of all sizes. Scanning can be completed in less than a half hour with the Steinbichler Comet L3D scanner. Its quickness is partially attributed to the scanner’s processing power and the turn table on which a part is mounted on. While scanning, the turn table will automatically turn the part at different angles to make sure that all necessary data from the part can be collected. The scanner itself captures millions of data points a second, providing an immense amount of surface detail for each scan.

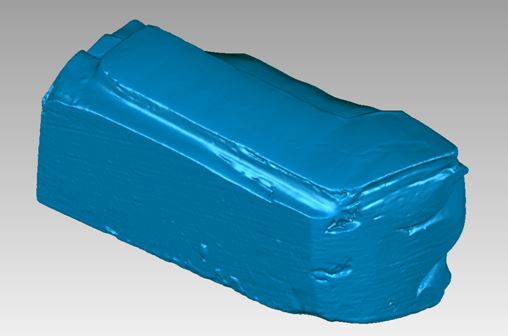

When scanning is completed, it produces a mesh STL file. Once it is created, the mesh goes through post processing using our editing software, Geomagic Wrap. This program is specifically designed to edit mesh data with ease and can clean any distortions that may have been picked up while scanning, such as holes, scratches, or bumps. The completed mesh can be seen in the image below. It shows all the small details captured by the scanner. If needed, the STL file can later be brought into physical form with a high level of accuracy through 3D printing.

NeoMetrix Advantage:

This case demonstrates some of the capabilities that we demonstrate on a daily basis:

- Highly accurate model.

- Capture small details.

- Quick turnaround for the customer.

- Eliminates guess work.

- Digital file can be preserved for future use.

“We have worked with NeoMetrix on a few projects over the last couple years. They have been very flexible in accommodating our ever changing needs. Some of our projects consisted of high-res scans of small parts with a .STL mesh data output . Others required them to scan portions of an entire motorcycle on location or in our trailer with surface data supplied as the RE data. Whatever the project was NeoMetrix always stepped up to the challenge and provided us with the data sets we needed to expedite our projects and make them come to fruition in acceptable time. NeoMetrix saved us time, money, and expedited our time to market on all these projects. They have all the technology, expertise, and tools to provide top notch reverse engineering and prototyping solutions, are great to work with, and deliver results very quickly.”

– Bart Rogowski, Founder & Owner of TST Industries

Epoxy mold to be scanned

L3D Comet scanner used

Epoxy mold scanned data

TST Industries’ machined part