Problem:

Sporting Goods needs to reproduce a series of parts in order to put a new firearm into production. This requires a set of 3D models and 2D Drawings.

Traditional Method:

Hand measurements are normally used to pull off dimensions and radiuses. However, the complex shapes and angles were not features that could be accurately measured by hand.

NeoMetrix Solution:

3D Laser Scanning:

Using Konica Minolta’s Range 7 with a tolerance at .0015” the 3D mesh was brought into software to begin modeling. Requiring a fully parametric model, the Rapidform XOR software was chosen for its ability to not only create a parametric feature tree but to export out a solidworks file.

- Laser scan with Konica-Minolta Range 7 3D scanner accurate to .0015”

- Rapidform to align and merge multiple scans (Figure 2)

- Curves and sketches developed based upon scanned data to facilitate solid modeling.

- Accuracy analyzer used to verify accuracy of final model to original part.

NeoMetrix Advantage:

- Complex geometry accurately captured.

- Quick turnaround time.

- 100% Editable Solidworks part file to make future design changes.

- Ability to make a rapid prototype to check fit parts to existing mates.

Solidworks Live Transfer:

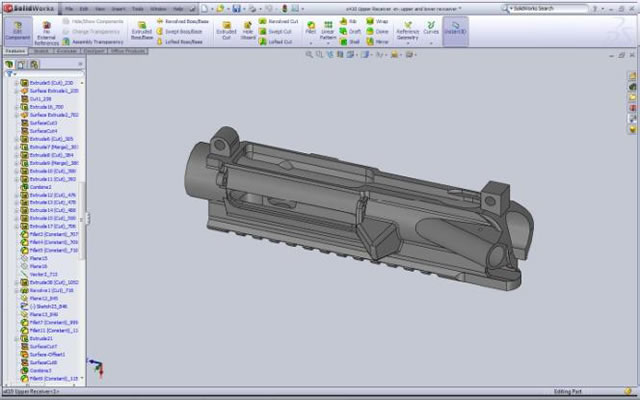

The machinist for Sporting Goods was familiar with Soildworks to create drawing and requested the final model be a Solidworks part file. Using Rapidform’s Livetransfer feature we can bring every feature in the parametric tree into the requested file type, giving him the ability to edit and change 100% of the delivered model.

Get Started Today!

Figure 1 – Original Part

Figure 2 – Laser Scanned Data

Figure 3 – Final Solidworks Model