Reverse Engineering a B747 Support Beam

DER Services contracts NeoMetrix to re-engineer aircraft hardwareThe Problem:

DER Services, Inc is an aeronautical engineering project development and consulting company which provides FAA DER approvals and engineering services to the aviation industry on a global scale. As part a of a modification to a Boeing 747, it was discovered that a support beam was bent under load and was no longer usable. Normally the customer would order a replacement part from the manufacturer. However, in this case, the component was no longer available for purchase. Reverse engineering of the existing component was the only alternative course of action.

Boeing 747

Traditional Method:

When replacement parts are no longer available, reverse engineering is the only option. Traditional measurement tools, such as calipers, tape measures, rulers and plumb bobs, are prone to inaccuracy and are not particularly useful for measuring the complex curvature associated with aircraft structural components. Hand measurements must then be manually input into a computer in order to generate the required 3D model and 2D drawings for manufacturing

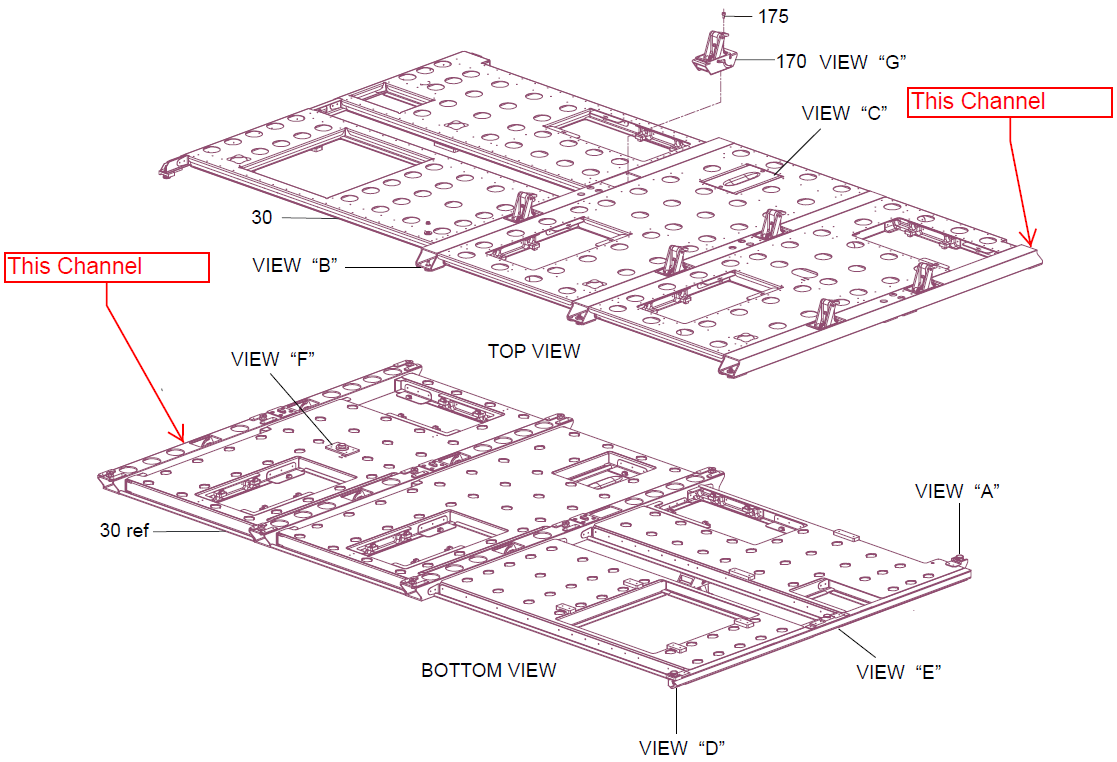

Beam Assembly

Beam Assembly Drawing

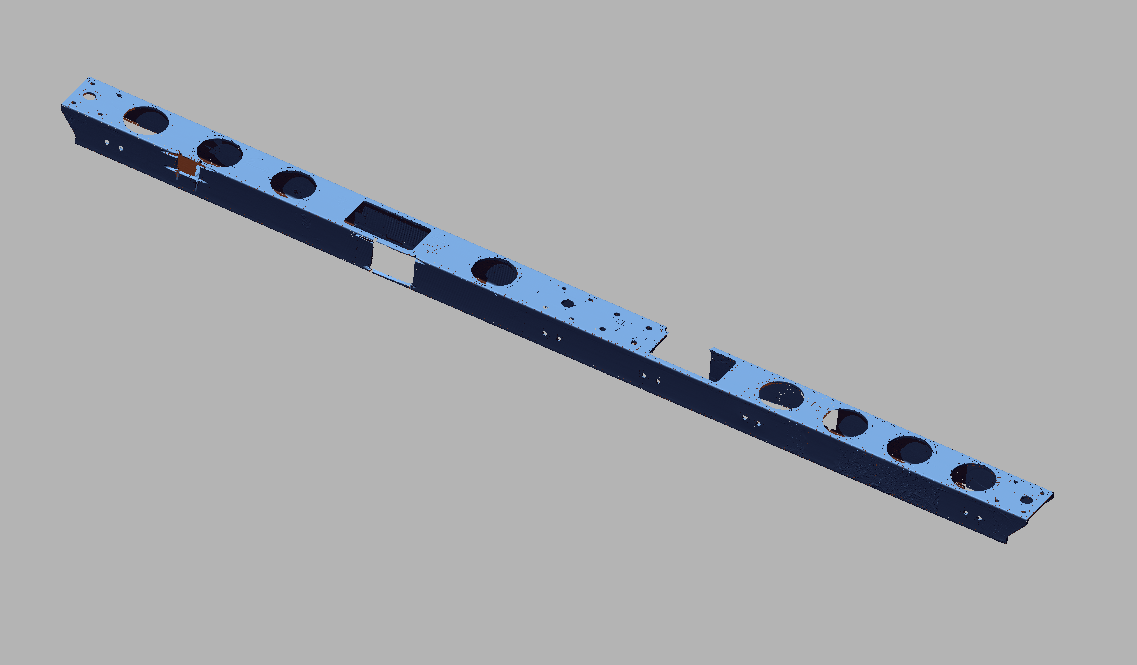

Beam to Be Scanned

NeoMetrix Solution:

The NeoMetrix method of reverse engineering employs the use of 3D scanning technology for rapid and accurate data collection of complex geometry. The scanner of choice for this project was the Zeiss Comet L3D. The beam was scanned into CometPLUS software. The captured data was directly output as a triangulated mesh or STL file.

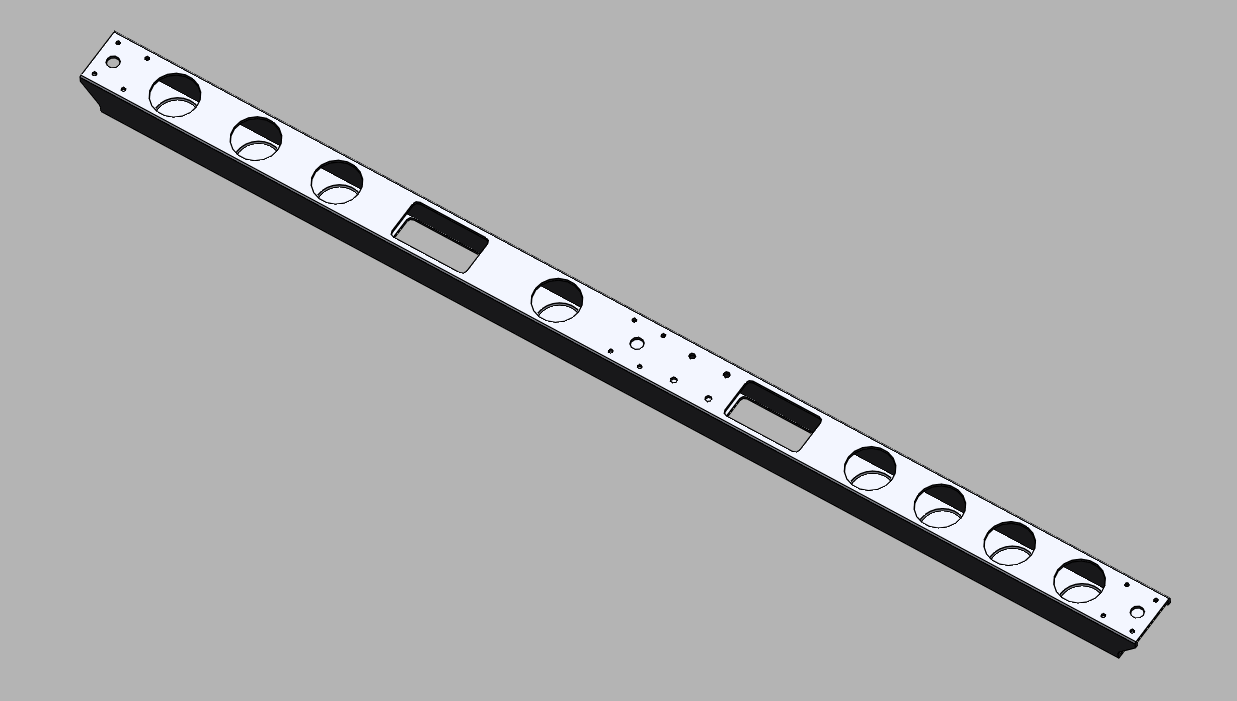

This mesh was then imported into Geomagic’s Design X reverse engineering software, where it was used as the guideline for generating the new CAD model of the part. Cross-sectional sketches were developed based upon the scanned data and subsequently used to generate solid bodies through traditional modeling methods, such as extrudes, lofts & sweeps.

Design X also allows for comparison of the final model back to the original scanned data to ensure accuracy to the original part while simultaneously pursuing the original design intent.

The final model was exported in STEP format for import into the customer’s CAD system for final review and manufacturing.

NeoMetrix Advantage:

Reverse engineering through 3D scanning ultimately produces a more accurate part than traditional methods of data collection and manual modeling. This is particularly true on aircraft components that are comprised of complex contoured surfaces that are virtually impossible to measure by hand. A more accurate model then results in a more accurate replacement part which is more likely to fit properly when installed, reducing the need for costly rework and scheduling delays.

Raw Scanned Data

Final Beam Model

About DER Services

DER Services, Inc is an aeronautical engineering project development and consulting company which provides FAA DER approvals and engineering services to the aviation industry on a global scale.

DER Services specializes in issues related to aircraft and aircraft component certification, structural repair design, analysis, and testing. Our team possesses the wealth of experience required to efficiently complete projects – whether small or large, simple or complex – within budget, and on schedule. Our goal is to work closely with each of our clients in order to provide the best possible engineering support without sacrificing the integrity of the product being delivered.

On staff, we have FAA Designated Engineering Representatives (DERs) that review and approve data for aircraft modifications. We also specialize in obtaining Supplemental Type Certifications (STCs) for our customers.

DER Services, Inc.

3836 St. Lucie Blvd

Fort Pierce, FL 34946

St. Lucie County Int’l Airport

Phone: (772) 873-1295

Email: sales@derservices.com

www.derservices.com

DER Services, Inc.

5330 Stadium Trace Parkway, Ste. 340

Birmingham AL 35244

Phone: (205) 682-9694

eFax: (206) 201-8197

Email: sales@derservices.com